22 hp briggs and stratton valve clearance

Log in.

Valves control the flow of fuel vapor into the combustion chamber and the flow of exhaust gases leaving the engine. Faulty or dirty valves may stick and can develop pits, cracks or grooves that cause the engine to lose power and fuel efficiency. WARNING : Always read the engine and equipment manual s before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. Find all Engine Safety Warnings. Before you can service or repair the valves, you need to remove the engine components that interfere with the engine valve. In order to properly inspect your engine valves for maintenance or repair, you need to remove them from the engine. Find the type of engine valve retainer and follow our step-by-step guide below.

22 hp briggs and stratton valve clearance

.

Step 1: Apply a small amount of valve lapping compound part number - a fine, but abrasive paste- to the valve face and insert the valve into the valve guide. Use the screwdriver to gauge the piston's range of motion. Care Products.

.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. I usually check and adjust the valves about once a year and hadn't done it yet on this engine. Couldn't get a. The specs on this engine call for.

22 hp briggs and stratton valve clearance

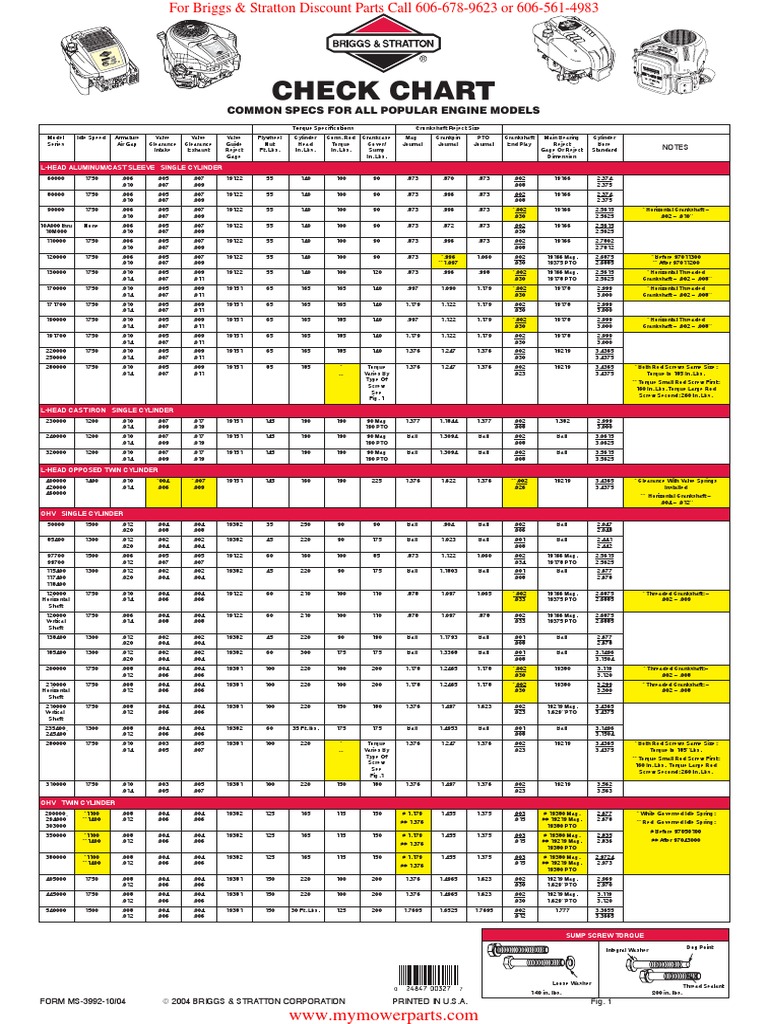

When doing small engine repair and maintenance, you may need to find specific parts and specifications for your engine. Knowing your small engine model number also provides basic specifications such as valve settings, bore, stroke, etc. Learn about the latest products, step-by-step instructions on how to locate your engine model number and more. Careers About Us. Find a Dealer. Residential Engines. Racing Engines. Standby Generators. PowerProtect View all Models.

Shrimp peeler

Then, slide the retainer off the valve by shifting it with needle nose pliers so that the large part of the keyhole is directly over the stem. Gummy deposits on the intake valve go hand in hand with a decrease in engine performance, often because the engine has been run on old gasoline. Use both thumbs to compress the spring until the valve stem extends through the large end of the keyhole slot. Recommended Communities. Log in. If the engine design does not permit the upper jaw to fit over the top of the valve chamber, insert the upper jaw into the chamber over the top of the spring, so that the spring is between the tool's jaws. Easy Features. Model Series 28N, 28Q, 28U, 28W, , , , exhaust push rod has a red band of paint for identification and is steel. Step 2: Wet the end of the lapping tool suction cup and place it on the valve head. Step 2 : Place the push rod guide on the cylinder head and attach the mounting bolts, using a torque wrench. With the valve spring compressed, remove the retainer. Removing the valves for keyhole retainers requires some patience. Why engines matter. Step 6 : Reinstall the crankcase breather and other engine components.

.

Step 2 : Place the push rod guide on the cylinder head and attach the mounting bolts, using a torque wrench. Step 9 : Remove and inspect the valves, guides and seats following the steps below. Step 1: Apply a small amount of valve lapping compound part number - a fine, but abrasive paste- to the valve face and insert the valve into the valve guide. Then, for final tightening, proceed in increments of roughly one-third the final torque. When I pull it into the barn after mowing for hours and flip the hood up, dust which has attached itself to small amounts of oil on the side of the engine is smoking or steaming. Then, install the rocker arm assemblies while holding the rocker arms against the valve cap and push rod. Step 1 : Valves with keyhole retainers do not require an additional retainer. That's by the book. Step 4 : Remove the rocker arm bolts with a socket wrench or nut driver. Yes, I clean the engine, but I'm not anal about it. Press them into place. View How-To Articles. Coat the rocker arm stud threads with a hardening sealant and install the rocker arm studs, using a socket wrench. Label the bolts if necessary, to ensure proper installation later, since they may be of different lengths.

0 thoughts on “22 hp briggs and stratton valve clearance”