Air compressor unloader valve

Same day shipment. Product experts available. Customers rate us: 4.

A reciprocating air compressor is a positive displacement mechanical device that uses a cylinder and crankshaft-driven piston to produce compressed air. An unloader valve is a small and essential part that ensures the effective, efficient operation of a reciprocating compressor. A compressor unloader valve is a small part, usually sized between 4 and 5 inches. If the unloader valve cannot release the air, the built-up pressure might prevent the motor from starting. Others have an integral valve installed under the pressure switch. The compressor pump, which is attached to the motor shaft, also stops.

Air compressor unloader valve

The air compressor unloader is valve is a small, but important, part of the reciprocating piston compressor. It blows off the pressure inside the discharge pipe when the compressor stops. There is another type of unloader valve , which can be found at the inlet of rotary screw compressors , also called inlet valve or loading valve. Air compressor unloader valve. The output of the piston compressor is connected through a pipe to the air receiver. When the compressor stops, the pressure in this pipe is blown off to 0 bar atmosphere. This is the ssssssshhh sound you will here when the compressor stops. At the same time, a check-valve makes sure that not the whole air receiver tank flows empty, but only this small pipe. When the compressor starts up again, and this pipe would still be under pressure, the electric motor will not be strong enough to turn the compressor. On smaller units, this valve is often mounted on, or inside, the pressure switch.

Its function depends on the behavior of the solenoid coil and the pressure differential of the system at least 0. GraterFang Jan 25, General 2.

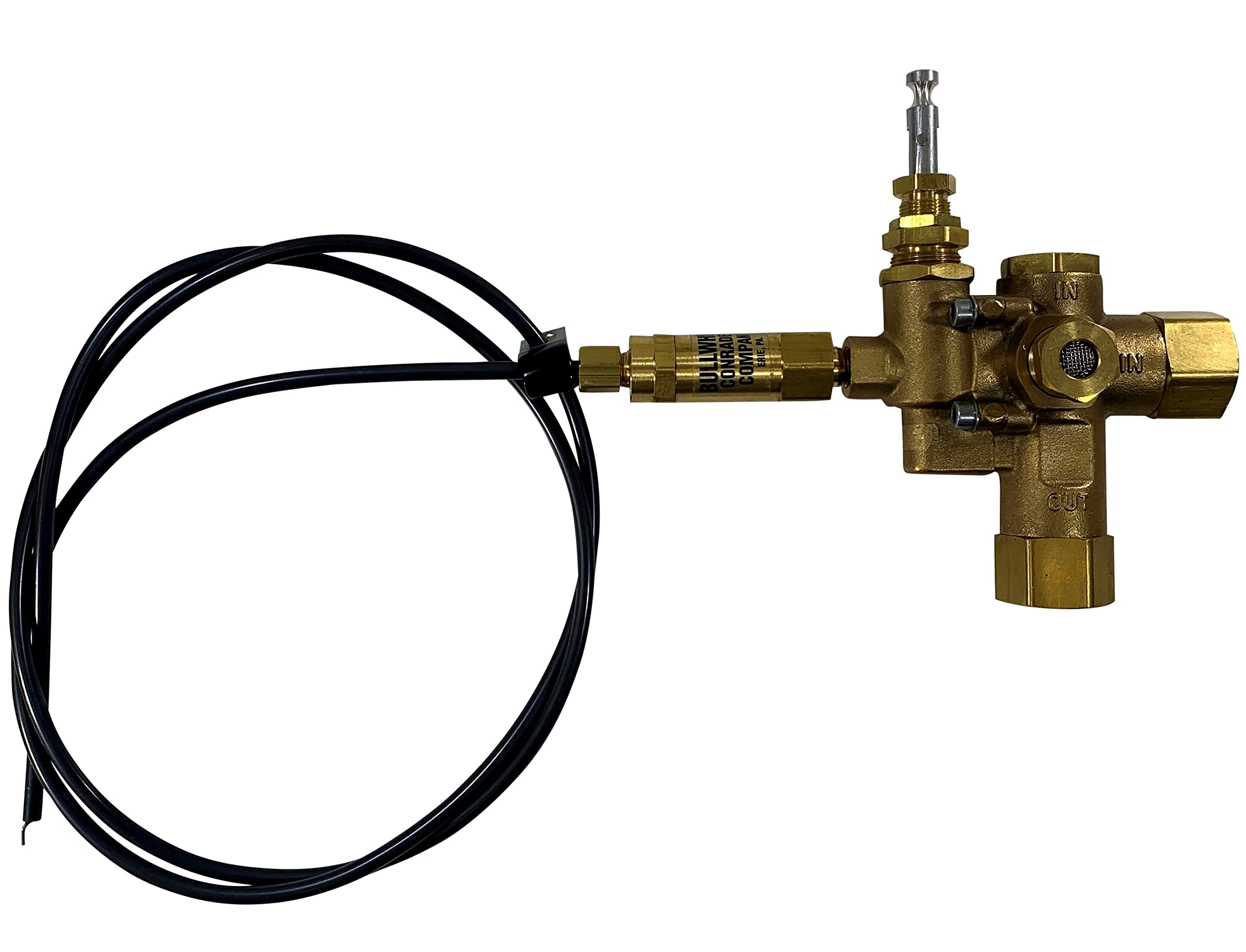

There are few components on an air compressor that can multi-task quite like the piloted unloader valve. This single component can activate an engine idle control, divert air from the tank when it reaches the top pressure setting and can reduce oil consumption by equalizing pressure between the pump and check valve. The following blog post will help you understand the piloted unloader valve by pointing out its components, explaining how it works and describing the adjustment process. The diagram below shows the components of our most common piloted unloader valve, part number B. Piloted unloader valves combine a pilot valve and an unloader valve to run an air compressor continuously.

Same day shipment. Product experts available. Customers rate us: 4. An air compressor unloader valve is a device used by air compressors to release the trapped air inside the compression chamber and tank discharge line when the motor stops. This allows the motor to start up easier. In general there are two types of air compressor unloader valves, electrical and mechanical. Figure 1 shows an example of an electrical air compressor unloader valve. Extracting the air by the unloader valve is essential for the compressor motor to start again without any effort. Otherwise, the generated load by the air in the compression chamber and tank discharging line creates a high initial torque that the motor may have difficulty overcoming.

Air compressor unloader valve

You are here Home » Automotive Tools » Air compressor. But, have you ever noticed your air compressor cycling on and off frequently? One possible reason behind this nuisance is the presence of excess pressure in the air tank. The solution? Install an unloader valve on your air compressor.

Epsa health

Compressor Unloader Valves. One of the reasons is that this valve type is suitable for larger flows of heavy air compressors compared to direct-acting valves. Proper maintenance steps protect your compressor components from excessive repairs. It also minimizes friction loss within the compressor, leading to increased productivity. I have no reference for how this is supposed to work. Unloader valves are located on top of or inside the pressure switch in smaller reciprocating air compressors. This will also help reduce any corrosive damage that could occur due to high heat or excessive cycling. When the tank pressure drops back down to the predetermined setting on the pressure switch, it causes the switch to trip again. This allows the motor to start up easier. This leads to increased DoE Doe Mean Time Between Failure and decreased maintenance needs, which will also lead to a decrease in running costs.

On a reciprocating, rotary screw, and even fossil fuel air compressors, compressed air can be trapped over the piston when the compressor reaches the cutout pressure and stops.

A new unloader valve can save you significant time and expenses. If the unloader stays open, you will hear a continues leak of compressed. It blows off the pressure inside the discharge pipe when the compressor stops. A bypassing type of unloader valve allows the excess compressed air to escape, thus keeping it from building up within the compressor. Detach the valve. What benefit does an unloader valve provide to the operation? It may not display this or other websites correctly. What Is the Purpose of an Unloader Valve? Air chuffs out intake, pressure does not build. Loosen locknut 1 by turning counterclockwise several full turns. You are using an out of date browser. The air entering this chamber pushes the piston down, which allows the air trapped in the unloader valve chamber to be discharged into the atmosphere through the outlet If pilot valve does not unload as tank pressure approaches PSI, slowly turn top end setting 4 counterclockwise until pilot starts to unload prematurely at PSI. The constant cycling of a compressor can wear down the internal parts over time.

0 thoughts on “Air compressor unloader valve”