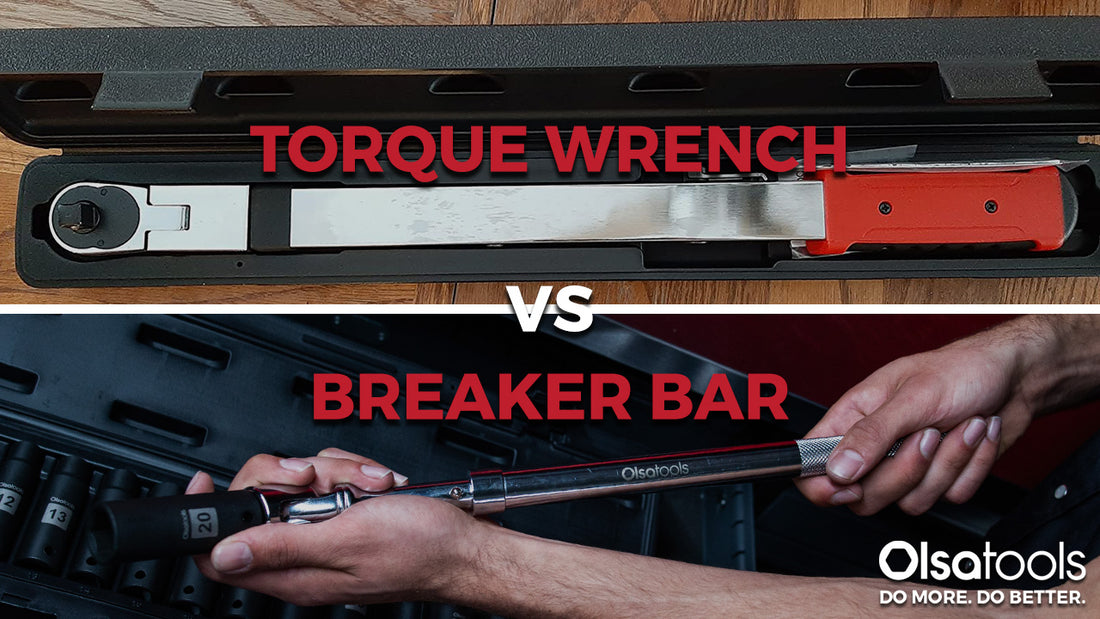

Breaker bar vs torque wrench

Our mission is to empower mechanics to achieve more in everyday projects by providing them with accessible, high-quality tools and accessories that accompany them for a lifetime. Working with nuts and bolts can be challenging, so having the most convenient tools for breaker bar vs torque wrench job is essential to complete your fastening tasks without aggravation or stress.

Do you need clarification about the difference between a breaker bar and a torque wrench and help to select which tool best fits your task? Having the appropriate tools is essential when working on vehicles or other machinery. Breaker bars and torque wrenches are two standard tools used for this task. However, they serve different functions. Each tool is engineered with its own specific goal in mind. Breaker bars are specifically designed to break free tight, frozen and rusted fasteners; torque wrenches feature mechanisms which exert exact amounts of torque onto fasteners. These tools are convenient when overtightening is not an option, such as working with spark plugs, lug nuts, engine building or assembly.

Breaker bar vs torque wrench

The short answer is no, as you can cause quite a bit of damage to them. Read on to learn about the differences between the two and whether you can use the breaker bar instead of a torque wrench. A torque wrench is a precision tool designed to help you do up nuts, bolts and other fasteners to a pre-set value and no more. This is important as each faster with its own material type and grade has a maximum amount of torque that can be applied to it. The handle of the torque wrench will usually have the torque value marked on a calibrated scale which can be pre-set. The indicator, be it a click type, a digital or a beam, will tell you when you have applied enough torque. Especially those with a main spring inside which can weaken and loosen over time. Being a precision tool means that a torque wrench should be handled and stored correctly. If it gets damaged, then it can lose its effectiveness and not give you the correct torque. Too little and things can fall off. Click type, digital, slip type, beam type, split beam and intelligent. The most common is the click type which is purely mechanical. These are readily available and can be cheap, although you can get better quality with a higher price. For the home amateur it may not be necessary as the accuracy of those cheap ones can be very good. The click type works by setting the torque value at the handle with the adjuster nut to the desired value on the calibrated scale.

Conversely, a breaker bar is a heavy-duty hand tool used for loosening frozen nuts or bolts and has no torque control or ratchet mechanism. The Alliance.

If you are a DIY enthusiast, you might have encountered the dilemma of using a torque wrench as a breaker bar. While both of these tools look similar, they serve different purposes. A breaker bar is used to loosen stubborn bolts, while a torque wrench is used to tighten bolts to the preset torque to avoid overtightening or under-tightening. So, can you use a torque wrench as a breaker bar? A breaker bar is built with extra strength and maximum leverage to loosen stubborn bolts or nuts. Did you realize just what I said?

Drill and Driver. The basic safety rule is to loosen and tighten the nuts and bolts properly when dealing with any machinery. Most people use a Torque Wrench or a Breaker Bar to complete this operation correctly. Both tools are the same in terms of functionality. However, they are distinct in their own characteristics. In addition, both beginners and specialists are perplexed as to which instrument is the most effective. Hence, it is a useful tool for loosening tight fasteners and unbolting them. Moreover, the breaker bar is also known as a power bar. Because of its lengthy non-ratcheting bar, it generates enough torque and force. A torque wrench differs from a breaker bar in two ways: first off, a torque wrench can readily tighten and loosen bolts for starters, whereas a breaker bar is mostly used to loosen bolts.

Breaker bar vs torque wrench

The breaker bar and the torque wrench are two of the essential tools for anyone dealing with fixing a car. The key difference between a breaker bar and a torque wrench is their purpose of usage. A breaker bar helps loosen stuck bolts with mass torque. In contrast, a torque wrench is useful for tightening bolts with a specific torque. These tools share more dissimilarities. Continue reading the article as we discuss the key differences between a breaker bar and a torque wrench. A breaker bar or a power bar is a long non-ratcheting bar used with wrench-style sockets to break securely tightened bolts, nuts, or screws. Torque wrenches refer to a specific type of wrench that has a function to set a specific torque while tightening fasteners.

Candice elizabeth nude

Thus, applying excessive force to the torque wrench or using it in ways it was not designed for can cause it to lose its structural integrity. Top Articles. Ratchet Mechanism 5. If it's just a dept store brand wrench, I would look into doing it yourself if needed. On my other bike, the spec is Nm lb-ft! The outfit will tear, right? The alert can be a clicking sound in case of a click-type wrench , beep sound digital type , or will display the reading in case of beam type. These are meant to tighten nuts and bolts to a specific point and no further. Most commonly, breaker bars are used in automotive repairs, construction, and situations requiring forceful loosening, such as when rusted or stuck fasteners need to be freed. So, breaker bars are easily replaced, while torque wrenches are not. They're interchangeable really. The slender and precise design of a torque wrench is not built to handle the sheer force required in breaker bar applications. Various torque wrench brands on the market offer different features and benefits to meet specific user needs and budget constraints. If you need to loosen stubborn nuts and bolts that require too much effort, yes, you need a breaker bar. When you turn the handle, it applies force to a spring or deflecting beam mechanism inside the wrench.

Our mission is to empower mechanics to achieve more in everyday projects by providing them with accessible, high-quality tools and accessories that accompany them for a lifetime. Working with nuts and bolts can be challenging, so having the most convenient tools for the job is essential to complete your fastening tasks without aggravation or stress.

On the other hand, breaker bars are more hardcore. I would trust a manual method of calibration before a HF digital gauge, unless it has also been tested and calibrated. This type of torque wrench is the most advanced and comes with features like Bluetooth connectivity, data logging, and torque-angle readings. Breaker bars are mostly built with solid metal for heavy-duty work. This type of torque wrench is designed to last longer than a click type and to be more of a professional kind of tool. Do not use the universal joint extensions with torque wrenches as they have a lot of play at the joints and may the accuracy of the effective torque applied on the fastener. A breaker bar is built with extra strength and maximum leverage to loosen stubborn bolts or nuts. Im from Israel, there's no one that does that here. Do you need clarification about the difference between a breaker bar and a torque wrench and help to select which tool best fits your task? You find you use it a lot. I have a snap on beam type where you do not need to reset it after using it and it only works in clockwise, I can't even loosen anything with it as it does not go in that direction. On the other hand, torque wrenches are more delicate and far more precise tools.

Thanks, can, I too can help you something?

As it is impossible by the way.