Cummins top stop injector adjustment

Log in. Sign up.

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method D. Included is the recommended procedure for checking and adjusting crossheads. We'll discuss the effects of crosshead adjustment related to valve operation. This is a Top Stop adjustment fixture It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft.

Cummins top stop injector adjustment

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. Your manual will no doubt show you this, but one dial registers via a long stem through a removed injector hole the piston position relative to crankshaft rotation, while another registers the push rod travel. Different thicknesses of rocker box gaskets are available to move the low mounted rocker rollers in or out of contact with the cam lobe. One gasket choice has to provide a satisfactory average for two cylinders. If you disturb an old engine to change these, you must pull the housing end plugs to renew the "O" rings. Otherwise leakage is pretty much guaranteed once its all back together again. If all you want to do is a valve, injector set, then just follow the instructions in your manual. In a nutshell that might be: a Remove valve covers and Jake housings keep in order b Clean gaskets, throw an overhaul kit into Jake housings if high miles c Loosen all rockers, and remove the top rocker housings for replacement of rocker shaft "O" rings, same as lower housings. Reinstall, torque housings. The set point is part of the above pulley points, and the chart will clarify that.

The crossheads are exposed here to illustrate that one rocker lever operates two intake or two exhaust valves with equal tension. Close suggestions Search Search.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Forums Bookmarks New posts Search forums.

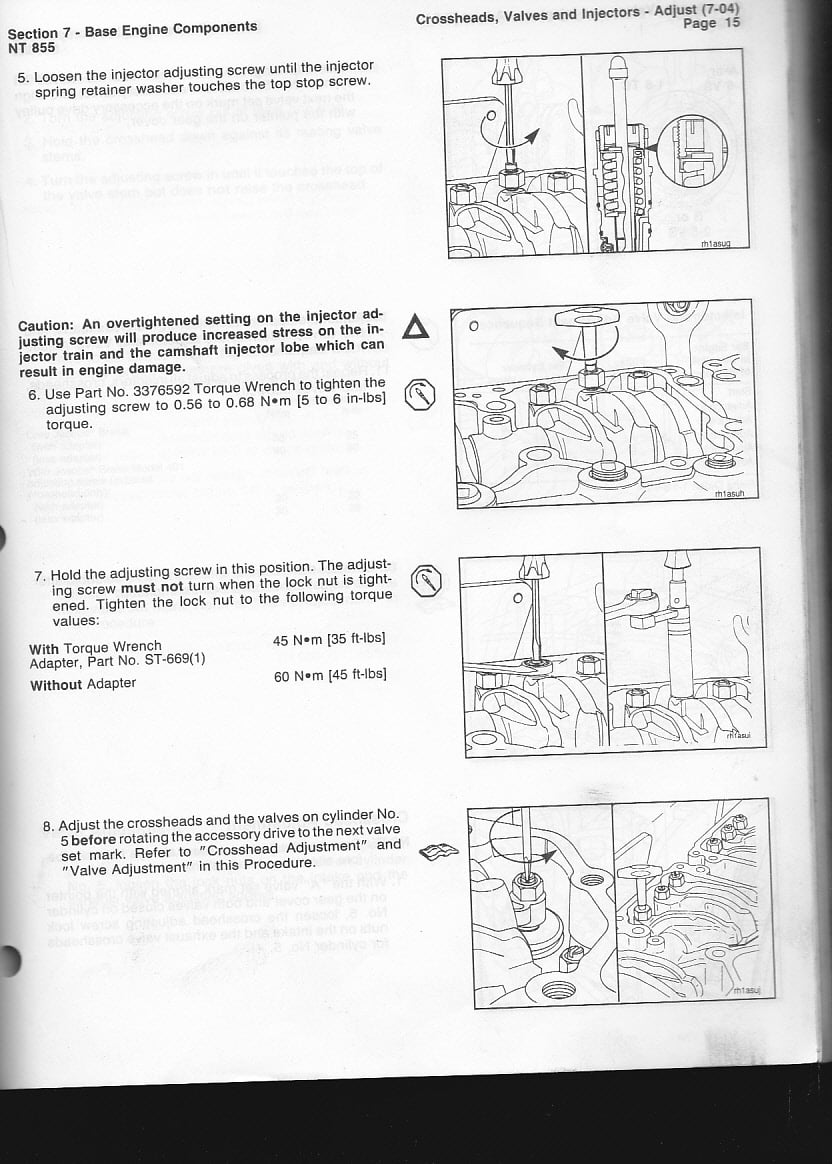

This post is mainly written to introduce how to adjust crosshead, injector and valves of Cummins NT diesel engines correctly. Pay attention to reading and you will learn more. Crosshead Adjustment. Note: Crosshead adjustment should always be made before attempting to adjust the valves. Loosen the locknut on the crosshead adjusting screw. Turn the adjusting screw out at least one turn. Hold the crosshead down against its mating valve stem.

Cummins top stop injector adjustment

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Forums Bookmarks New posts Search forums. What's new New posts New profile posts Latest activity. Members Current visitors New profile posts Search profile posts. Vendor Spotlight.

50 in tv bracket

The crossheads are exposed here to illustrate that one rocker lever operates two intake or two exhaust valves with equal tension. Before we get into setting valves and injectors, let's ask- ourselves a question. At this position both the jntake and exhaust valves are closed, providihg lash in the valve train to ensu re correct clearance settings. Sign up. For a better experience, please enable JavaScript in your browser before proceeding. Controles de Vuelo Controles de Vuelo Just need to be able to extend the end of the dial indicator so it can reach the top of the plunger right above the spring. This graph illustrates the approximate position of the exhaust valve adjustment point for any given cylinder. With the travel method, they have you setting the travel on the injector just before it starts to go into its travel if you are setting valves on 5, then the engine is TDC at 5 on the compression stroke and 3 is right behind it but just before the injector starts its travel. It's still running but I don't use it much now as that old Pete is hard on my body.. Zero Lash. Upon cranking the engine the truck will blow white smoke and I wonder if I may have damaged the injectors or if I still haven't primed the fuel system completely yet. You are using an out of date browser. About '73 Cummins came up with the NTA engines. Now I am looking at understanding how to set injection travel.

Follow along with the video below to see how to install our site as a web app on your home screen.

The next step was the NT xt. I went through and set the lash for valves and injectors using the torque method on the injectors. The two methods are torquing to preload the Top Stop plunger link and setting the non Top Stop plunger travel with the dial indicator. Construction and Manufacture of Automobiles From Everand. You must log in or register to reply here. Using the actuator, compress the rocker lever 2 or 3 times to completely seat the injector plunger. Zero Lash. Position the extension securely on top of the injector plunger flange. Thanks again! O number is and Date of manufacture is Fuel arriving late produces an incomplete burn, which leads to carboning and black smoke. For example, if the pointer is at IIA II , check for closed valves on cylinders 5 and 2; the injector will be metering on 3 or 4. About '73 Cummins came up with the NTA engines. Be sure to use the correct clearance specifications. Securely tighten the hold down into place in the rocker box housing.

Simply Shine

I think, that you are not right. Let's discuss it. Write to me in PM, we will communicate.

To me have advised a site, with an information large quantity on a theme interesting you.