Danfoss vfd fault codes

The frequency converter is an electronic motor controller The operating guide is intended for use by qualified intended for: personnel.

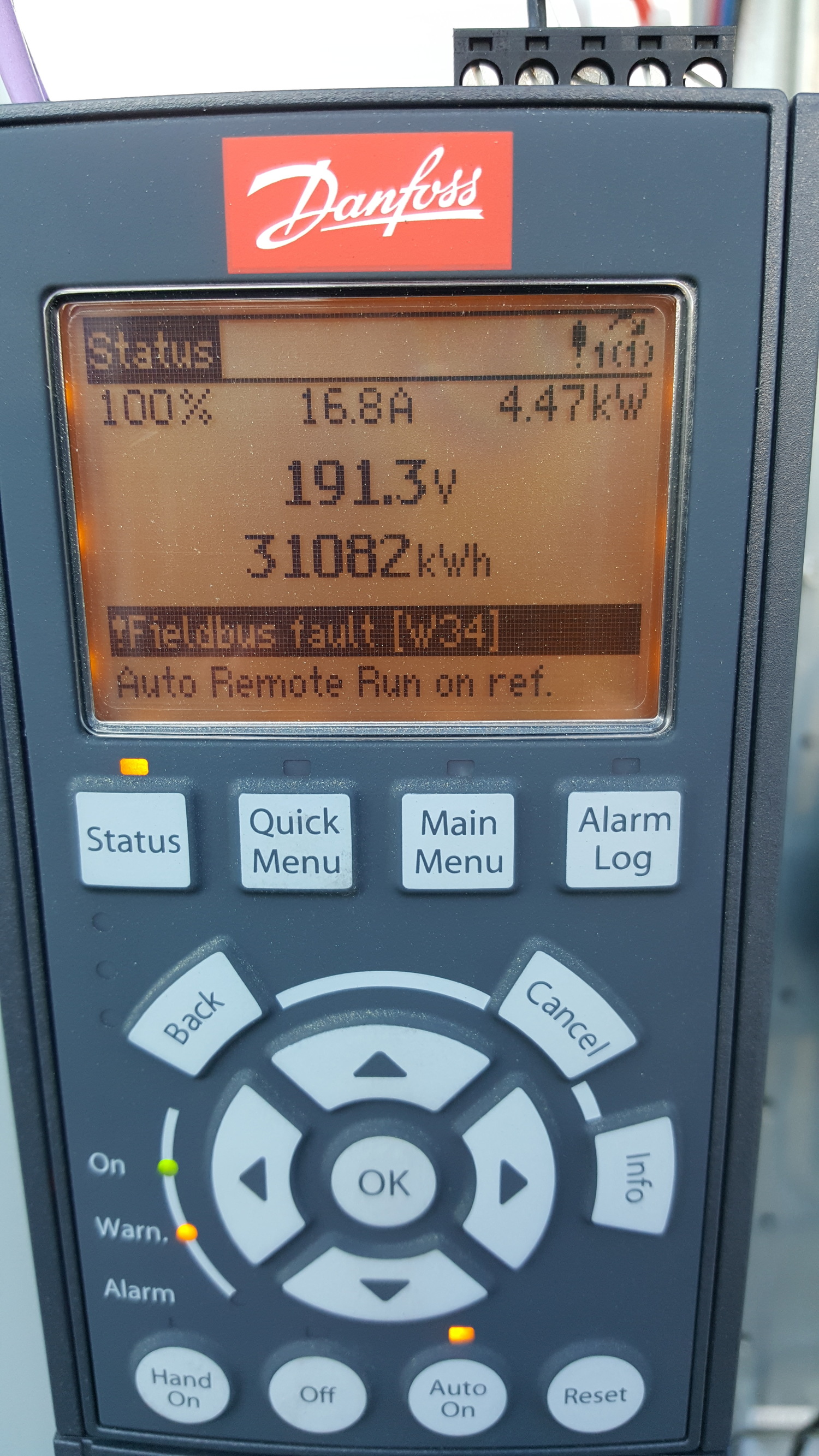

Safety note: To avoid electrical shock hazard- even after the power is disconnected- wait at least as follows before doing service on the frequency converter: V: 0. Warning Alarm Trip lock. The operation values shown on the display give detailed information about the status of the drive and the connected peripherals. These values are accessible also when warning and alarm messages are shown. RS or Profibus. Alarm with Trip lock An Alarm with Trip lock can be reset only after a complete mains off Display dark.

Danfoss vfd fault codes

.

Warning Alarm Trip lock. The motor was too warm when 3. Check the Sensor type do not match the used part Par.

.

Troubleshoot and fix your Danfoss products to ensure smooth operations and high reliability. Find links below to useful resources for Drives, Cooling, Heating and Industrial Automation product portfolios. For AC drives please contact your local sales office for fix and troubleshooting by certified service partners. Find everything you need as a wholesale cooling professional , including easy-to-use tools, guides, and product information. Find everything you need as a heating professional , including product information, installation support and free training courses. Find everything you need as an industrial professional working with Danfoss Sensing Solutions, including product support, how-to videos and free training courses. Find everything you need as an electric heating professional , including video links, warranty information, application manuals and product information. Find our video library for product troubleshooting, technical literature and frequently asked questions for supermarket applications. Are you in need of spare parts, commissioning assistance, training or trouble shooting?

Danfoss vfd fault codes

Update your app to the latest version or download the app to your device for the latest content and offers. Investing in the future of your operations starts with securing your systems. All Drives must be currently covered by an active Danfoss Drive warranty to qualify for the extension. Registration submission must include the company name, email address, and phone number for where the Drives are installed. Embrace electrification at scale without compromise.

Translink go card refund

Note Reset The max. Note: 4. Clean the ventilation vents and the change the filter pads 4. The Fan is defect 1. This can be done by using a freewheel diode or, alternatively, a 30 V or 50 V MOV for quicker response time across the coil. The ambient temperature is 1. Connect mains again. Wrong motor data 2. Manual Reset. Install equalizing cables between the system components. When an internal fault occurs, a code number defined in Failure to use qualified personnel to install, start up, and Table 7. Auto Remote Trip Safety note: To avoid electrical shock hazard- even after the power is disconnected- wait at least as follows before doing service on the frequency converter: V: 0. Use the slotted mounting holes on the unit for wall mount, when provided. The switching frequency is too 2.

Capacitor Reforming Procedure to condition the capacitors for the ideal Drives more than a year The capacitors will fully get drained out during its ideal time due to the internal ESR of the capacitor If we suddenly supply it with full voltage, there will be a high inrush charging current which leads to the breakdown of the capacitor In a normal scenario and for all the new drives, there is no need to do any additional precautions for Capacitor. But Capacitor conditioning can be carried out if the Drive was kept idle for more than a year The capacitors need to be slowly charged with controlled DC source and then only they can be used normally If DC source is not available then we can use series lamps for soft charge the drives with a small rating of MCB.

Check for proper grounding of the frequency power and at all times. The connected brake resistor is 3. Wrong motor data resp. Check the mains for possible sation device over voltage Note: 4. Matrice Declansare Matrice Declansare. Is this content inappropriate? Failure to perform installation, start-up, and maintenance by qualified 4. Brake Feedb. The control card voltage is less than 10 V from terminal Options are programmed in Warning indicator light Alarm indicator light parameter Response to Mains Imbalance. Par is too high 5. Check the mains for imbalance 4 Mains phase loss the imbalance is too high the voltage difference of the three phases must not exceed 3.

0 thoughts on “Danfoss vfd fault codes”