Dt466 engine specs

How much horsepower can a make reliably for highway use?

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling. It included the D 4.

Dt466 engine specs

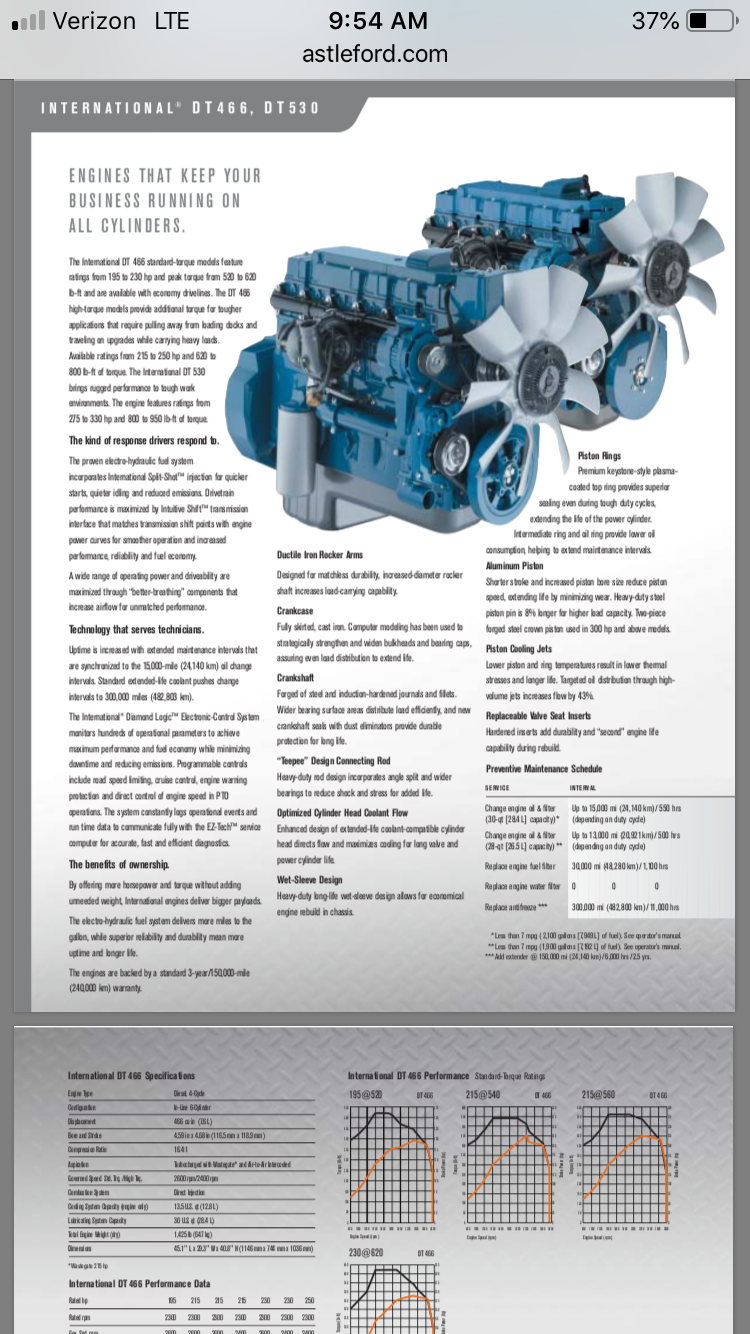

The Navistar DT engine family is a line of mid-range inline-6 diesel engines. With horsepower ratings ranging from hp kW to hp kW , the Navistar DT engines are used primarily in medium-duty truck and bus applications such as school buses , although some versions have been developed for heavy-duty regional-haul and severe-service applications. Prior to , Navistar International, then known as International Harvester Company , used the DT engine in farm and construction equipment. The Navistar DT diesel engines are of a wet-sleeve design. This means that the cylinder wall sleeve is a separately machined part that fits into the cylinder bores cast into the engine block. The cylinder sleeve is in contact with the engine coolant, hence the "wet"-sleeve. Navistar claims that the wet-sleeve design enhances durability because the consistent wall thickness of the sleeve allows for consistent heat transfer, ensuring the cylinders stay round during thermal expansion. Additionally, they state that the hardened cylinder sleeve is more durable and wear resistant than a softer, cast-in wall. Also, the replaceable cylinder sleeves protect the block from damage e. The wet-sleeve design also allows the engine to be rebuilt easily to factory specifications, sometimes without even removing the engine from the vehicle. This design is opposed to parent bore engines, where the cylinder walls are machined out of the bores cast into the block. International states that the uneven thickness of the cylinder walls causes the cylinders to become out of round during thermal expansion, increasing wear.

The other hurdle is the drive train. Diesel News Ford.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. They are oringally from farm tractor useage adpted to truck useage and they were very scussedfull with it. Yeah they are wet sleeved engine and you can actally rebuilt the engine in the truck without pulling the engine out of the truck frame.

The International DT engine is a 7. It also is utilized in the International CXT, a pickup truck built on the International ton hauler platform. Over one million DT engines have been produced. The DT is a turbocharged diesel. It is, according to Brattain, " the only high volume mid-range diesel engine with replaceable wet sleeve architecture. The DT utilizes six bolts per cylinder for head clamping. The purpose of the six-bolt design is to evenly distribute clamping force and improve the life span of the head gasket. Additionally, the DT design includes valve rotators and an oil cooler thermostat.

Dt466 engine specs

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which very much needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling. It included the D 4. The line shared a 4. Design features of the and series engines included grey iron blocks set up for plateau-honed wet sleeves of cast iron with a high chrome content.

Ulta beauty atlanta reviews

For , a twin sequential turbocharger system was employed for further improvements in throttle response, overall performance, and reduced emissions. Those have the P-pump like the Dodges, and went from 93 up until In the DT engines were updated once again for compliance with emissions standards. More than that you will need the HT-series if you want reliability. But to meet the stricter EPA emissions standards that had gone into effect in , International switched the bulk of its on-road DT engines over to the Caterpillar-designed HEUI injection system in the HEUI acronym representing hydraulically actuated, electronic controlled unit injector. Block Each block is carefully inspected for cracks or other signs of damage. Posted April 12, The two common ratings were and hp in trucks. Another truck I had was rated at hp and generated 18psi boost. The goal for the series engines, in particular, was to replace the aged yet highly venerable DT, which International planned to phase out of production.

All to current models used an HEUI hydraulically actuated electronically controlled unit injector fuel system. The P pump DT was actually used in select applications through the model year, but these are uncommon.

I think they went common-rail a few years ago, as the is still produced now badged "The Legend" and they are still going strong. The DT engines are of a wet-sleeve design. I had an flatbed truck that was origanally a hp DTb and it generated 15psi boost. That process is followed by the rods being honed to their usual diameter of original equipment, which provides for an even distribution of stress across the bearings. If you have repowered a truck that didn't have the DT in it from the factory, increasing the HP can also cause driveline and chassis problems. Come join the discussion about performance, modifications, troubleshooting, engine swaps, transfer cases, and more! The injection pump changed to a Bosch MW inline and both turbo and turbo intercooled engines were offered. In , the DT engines were updated once again to comply with stricter emissions standards. There were small numbers of PLN engines as late as Discover your best options! The goal for the series engines, in particular, was to replace the aged yet highly venerable DT, which International planned to phase out of production. However, the stroke was the difference in the latter engines, with all of them sharing a common, 4. Fairbanks-Morse 36A Engines Fairbanks-Morse was a well-established engine manufacturer when they started the development of their first four-stroke, high-speed diesel in

You are mistaken. I suggest it to discuss. Write to me in PM.

Completely I share your opinion. In it something is and it is excellent idea. It is ready to support you.