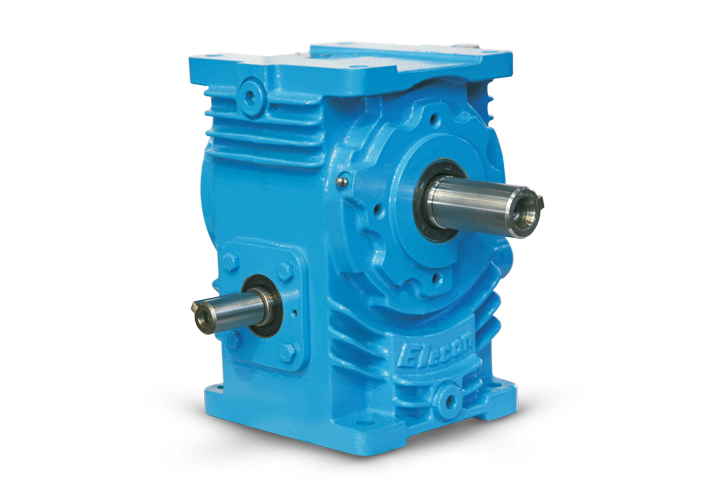

Elecon gear box drawing

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

He should thoroughly study and understand the instructions given in this manual. Precisely following of this manual will give trouble free working of the Gear unit. As such, in no case the Gear box to be opened by the unauthorized person during its warrantee period. Delivery Conditions : All the Gear boxes are dispatched with list of components packed in the box. This should be checked on receipt as per Packing-list and missing of any part to be reported immediately. The Gear units are supplied without oil filling. Recommended oil has to be filled up before commissioning the unit.

Elecon gear box drawing

.

Module 17 Propeller Sub Module The high-speed shaft rotation is not more than rpm.

.

Backstops have adequate capacities to deal with full rated torque. Location of shafts and direction of rotation, see dimension sheets Backstops have adequate capacities to deal with full rated torque. Motor bell housing available with or without motor. Overload slip clutches on request. Flexible coupling.

Elecon gear box drawing

He should thoroughly study and understand the instructions given in this manual. Precisely following of this manual will give trouble free working of the Gear unit. As such, in no case the Gear box to be opened by the unauthorized person during its warrantee period. Delivery Conditions : All the Gear boxes are dispatched with list of components packed in the box. This should be checked on receipt as per Packing-list and missing of any part to be reported immediately. The Gear units are supplied without oil filling. Recommended oil has to be filled up before commissioning the unit. Wherever grease lubrication points are provided, the grease filling is done from our works. The instruments like pressure gauges, temperature gauges etc are dispatched loose pack, shall be well protected in store. The packing, unless otherwise agreed contractually, complies with Packing guidelines.

Acrylic wash basin

Feeding the penetrating oil is carried out via bores in the machine shaft see Fig. Screw the cover on tight. Detailed Requirements. Vibration and shock forces at high loads. If this flushness cannot be reached during clamping, consultation is necessary. Skip carousel. Such systems must be relieved at a suitable location. It ensures that the gear units are maintenance-free. ZQ reducer difference: ZQ type is an involute cylindrical gear reducer, ZQ H type is a cylindrical gear reducer, which is formed on the basis of the ZQ type involute cylindrical gear reducer series. The gears should be turned slowly by hand at intervals, in order to ensure the oil is distributed over all parts in contact. The store will not work correctly in the case when cookies are disabled. How v. BUSH 1 9.

Verified Supplier. Have a requirement?

PLATE 1 Before undoing shaft connections, make sure that no torques are present at the shaft connection stresses within the system. The soft tooth surface reducer has a very wide range of applications, and is widely used in various packaging machines, conveyors and other low-power equipment. Vibration and shock forces at high loads. BUSH 1 2. The ratio of the number of teeth of the large and small gears is the transmission ratio. Figure 1 1 Machine shaft 5 Threaded spindle 2 Hollow shaft 6 Nut 3 Parallel key 7 End plate 4 Nut Instead of using the shown nut and threaded spindle, e. The ZQ reducer has two stages of transmission, and there are nine types of assembly. Cookies and Privacy. High-quality forged steel material, rigid cast iron box, and high-frequency heat treatment on the surface of the gear; 6. Figure 5.

0 thoughts on “Elecon gear box drawing”