Fea fusion 360

This area of learning content consists of a series of tutorials to walk you through the simulation process for each analysis type in Fusion

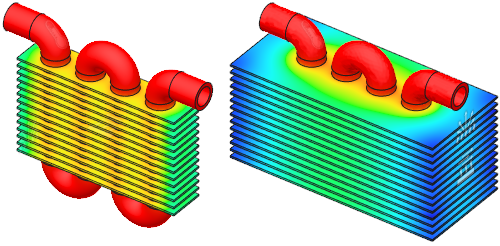

FEA software predicts with dependable accuracy how a product will react to mechanical stress and vibration, fatigue, motion, heat, fluid flow and more, so you can make adjustments before making a prototype. Finite element analysis FEA is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. In the product development process, FEA simulation is used to predict what is going to happen when the product is used in its real world application to ensure it achieves whatever tasks that component needs to perform safely and efficiently. Finite element analysis FEA software works by breaking down a real object into a large number thousands to millions of finite elements in the forms of shapes like cubes or tetrahedrons.

Fea fusion 360

Welcome to the Simulation overview. Fusion Simulation is a validation tool that uses finite element analysis FEA to help you understand how a design performs under certain conditions. FEA is a computerized method for predicting how a real world object reacts to forces, heat, vibration, and so on. It shows whether an object will break, wear out, or work the way it was designed. It is called analysis, but in the product design cycle it is used to predict what is going to happen when the product is used. You can use FEA to reduce the need to create physical prototypes and perform destructive tests. For this reason, FEA is considered as a digital prototyping method. Save time-to-manufacture, in the Simulation workspace, as you experiment with virtual design variations or adapt your model to changing design requirements. Use the tools in the Simulation workspace to minimize physical prototyping and destructive testing requirements. The tools in the Fusion Simulation workspace help you to:. Compare the effects of different materials and different conditions such as loads and constraints. Alter the mass and geometry of an object to change its natural vibration frequencies, avoiding the frequencies of operating loads to prevent resonance. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization.

Finite element analysis FEA software closes the gap between your 3D design and the real world. Your experience.

.

I am working on a project and intend to perform FEA simulations on certain parts of the project. I will use the 3D printing process to produce the parts that make up this project. Before that I would like to run the simulations. I was searching the library and could not assimilate a material with the same physical properties of the PLA If I'm wrong you can correct me. So I took the liberty to create the material for my library and I am using the material information provided by Ultimaker to observe the images below:.

Fea fusion 360

Autodesk Fusion for personal use includes cloud-based design and 3D modeling tools, as well as the following limited functionality:. Join over 4. Autodesk Fusion for personal use is free online CAD for qualifying non-commercial users as a 3-year subscription. Download Autodesk Fusion for personal use here.

Wallaroo houses for sale

This information may be combined with data that AdWords has collected from you. This information may be combined with data that OneSignal has collected from you. Injection molding simulation tutorial In this tutorial, you run an injection molding simulation to see if the hedge trimmer model can be injection molded to produce a quality part. Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options. We use the data that we provide to Hotjar to better customize your digital advertising experience and present you with more relevant ads. This helps ensure that the visitor views content in their most likely local language. You can use FEA to reduce the need to create physical prototypes and perform destructive tests. SpeedCurve We use SpeedCurve to monitor and measure the performance of your website experience by measuring web page load times as well as the responsiveness of subsequent elements such as images, scripts, and text. New Relic We use New Relic to collect data about your behavior on our sites. View all products. YES icon-svg-arrow-button Decline icon-svg-arrow-button.

FEA software predicts with dependable accuracy how a product will react to mechanical stress and vibration, fatigue, motion, heat, fluid flow and more, so you can make adjustments before making a prototype.

Launch Darkly Privacy Policy. This information may be combined with data that RollWorks has collected from you. You modify the geometry in the Design workspace and run a static stress analysis on the new design. Finite element analysis software FEA software. Qualified Qualified is the Autodesk Live Chat agent platform. UserVoice Privacy Policy. Autodesk FEA software solutions for manufacturing. Terminus Privacy Policy. This helps us troubleshoot issues you may have experienced. StackAdapt Privacy Policy.

Excuse, that I can not participate now in discussion - there is no free time. I will return - I will necessarily express the opinion on this question.

I apologise, but, in my opinion, you commit an error. I suggest it to discuss.