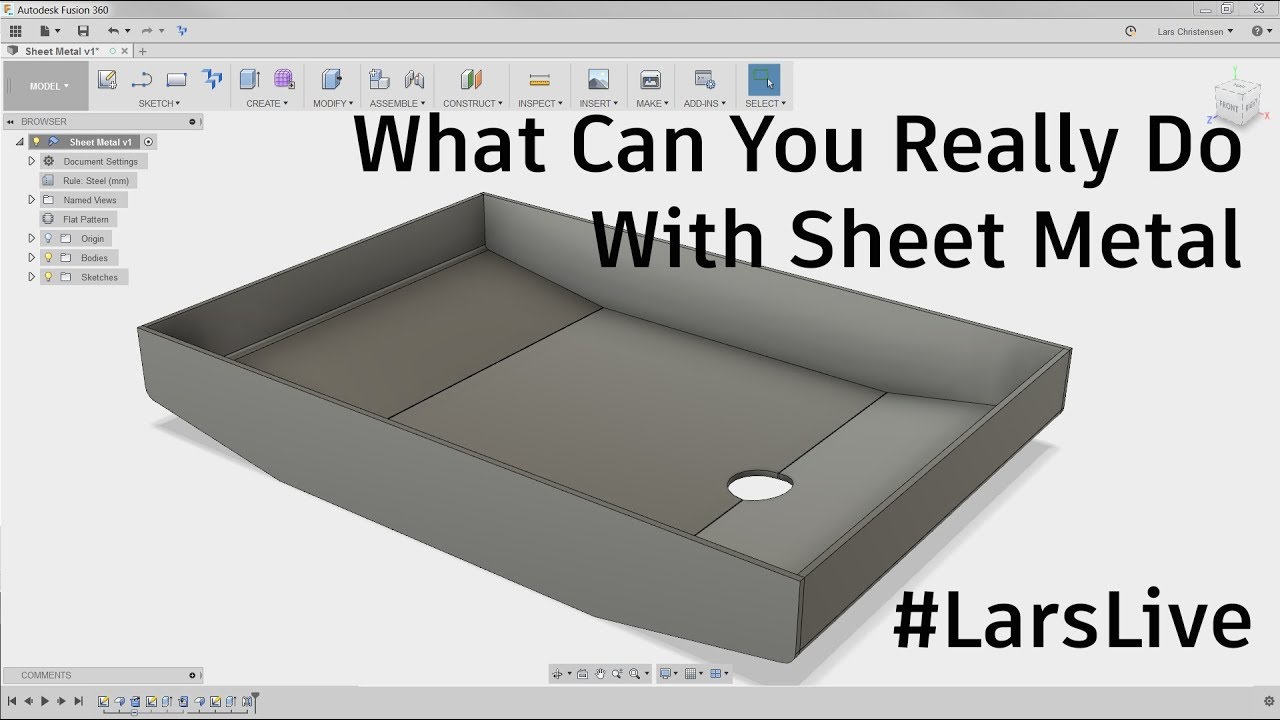

Fusion 360 sheet metal design

Forms Maintenance: Feb Thanks for your patience. Autodesk Fusion streamlines sheet metal fabrication and design, allowing you to design, test, document, and fabricate in a single integrated tool.

For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. You enter the values for these details, and then the software applies them as you design. For example, when you create a flange the bend is added automatically. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization. They may be set by us or by third party providers whose services we use to deliver information and experiences tailored to you.

Fusion 360 sheet metal design

.

Marketo Privacy Policy.

.

Sheet metal design software is the most critical component of sheet metal fabrication. Sheet metal is a common material across many industries, including automotive, industrial, and medical, because of its flexibility, durability, and tensile strength. As the name suggests, sheet metal is metal formed into thin, flat pieces using a portion of steel, aluminum, copper, brass, and other materials. It can be precisely cut and shaped into plates, sheets, or foils because of its unique characteristics. Sheet metal usually remains under 6 mm thick anything above 6 mm is a metal plate. You can measure this thickness in three different units: mils, millimeters, or gauges. A gauge is the thickness of the metal in relation to its weight per square foot — the higher the gauge, the thinner the sheet of metal. Sheet metal can be fabricated to build airplanes, cars, fencing, household appliances, coins, and much more, and it can be manipulated in several ways, such as:.

Fusion 360 sheet metal design

They each have their own benefits, but here are the two main reasons I would switch to using sheet metal design in Fusion What does this mean for you? Well, now with your subscription to Fusion , you will have access to all available functionality. In this post, we will take a deep dive into why you need to start using the sheet metal functionality inside Fusion Whether you have been bending sheet metal since the invention of the press brake or you just created your first flange, one flange command will improve your design process. Those traditional CAD tools out there make you memorize when to use different sheet metal commands in different situations. We just want to be able to get the job done. Fusion folds 5 sheet metal flange commands base, edge, contour, miter, and swept into one flange command. The command is aware of what is being selected and will automatically switch to the right command.

List of raw theme songs

HubSpot We use HubSpot to send you more timely and relevant email content. Stress-test and optimize in one integrated design environment. Qualified Qualified is the Autodesk Live Chat agent platform. This helps ensure that the visitor views content in their most likely local language. Learn more. Customize your advertising — permits us to offer targeted advertising to you These cookies collect data about you based on your activities and interests in order to show you relevant ads and to track effectiveness. Launch Darkly Privacy Policy. YouTube YouTube is a video sharing platform which allows users to view and share embedded videos on our websites. Call Tracking Privacy Policy. Strictly necessary — required for our site to work and to provide services to you. Frequently asked questions FAQs. Autodesk Research. StackAdapt Privacy Policy. Flexible parametric model tools. Dynatrace Privacy Policy.

Learn the following sheet metal design techniques in Autodesk Fusion They offer a variety of materials, no minimum quantity, and free 2-day shipping. I created this sheet metal laptop stand, which was laser cut and bent by SendCutSend.

Bing Privacy Policy. The data we collect helps us understand how you use our products, what information you might be interested in, and what we can improve to make your engagement with Autodesk more rewarding. Strictly necessary — required for our site to work and to provide services to you These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. What types of simulation are supported in Autodesk Fusion that enables the testing of sheet metal forming? Twitter We use Twitter to deploy digital advertising on sites supported by Twitter. Japan We use Yahoo! Learn the basics of sheet metal design in Fusion in the Autodesk Product Documentation portal. While the default K-Factor of 0. Twitter Privacy Policy. Naver Privacy Policy. This information may be combined with data that RollWorks has collected from you. Stress-test and optimize in one integrated design environment. Doubleclick Privacy Policy. Also, learn about downstream manufacturing workflows for sheet metal models.

I am sorry, it not absolutely approaches me. Perhaps there are still variants?