Ignition control module

The primary current for the ignition coil can be 10 A or more. The electronics in the ignition module, which switch this current on and ignition control module, become very hot due to this high current power loss. Therefore, all ignition modules have cooling surfaces or even heat sinks made from aluminium.

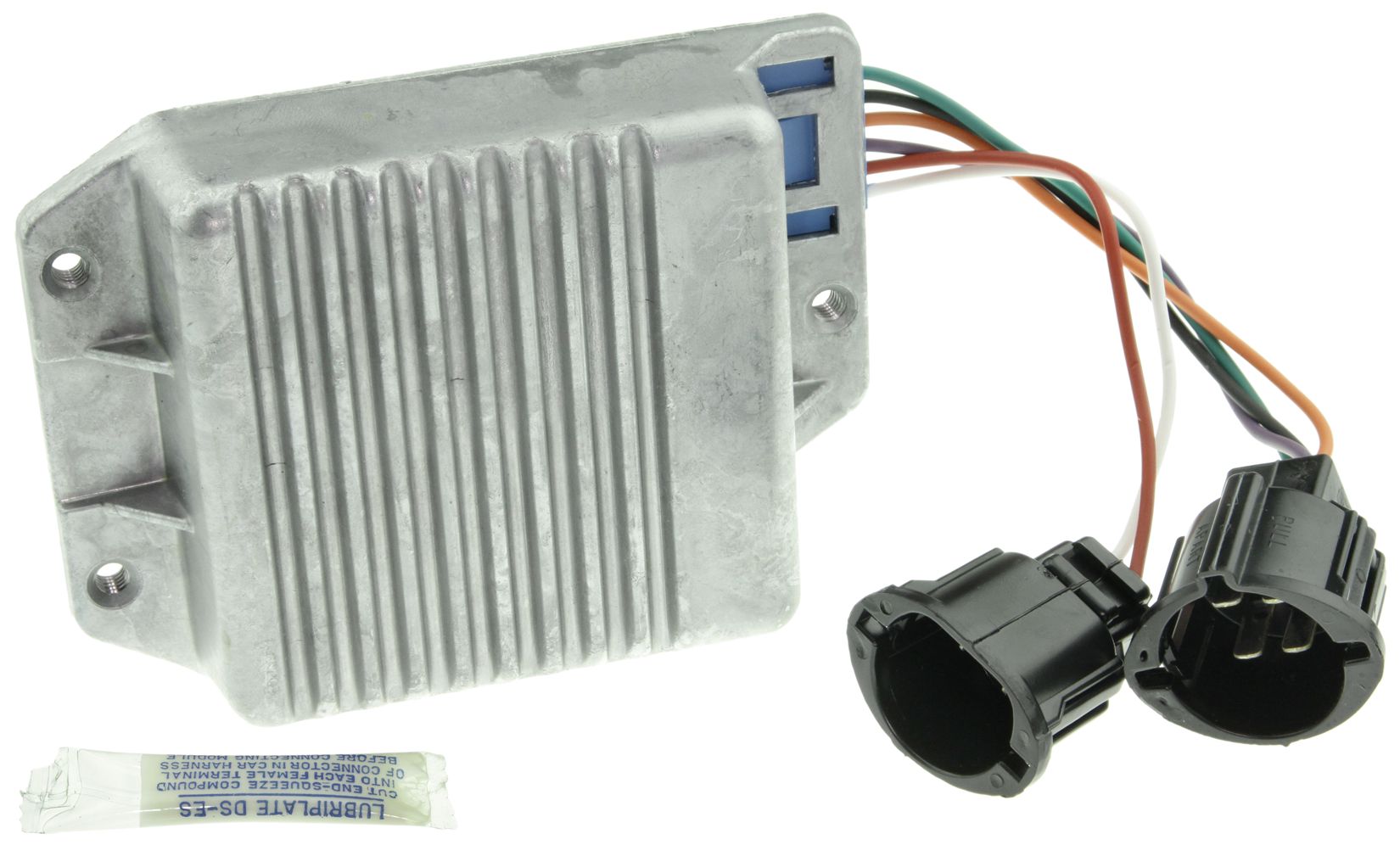

Image: Standard LX The ignition control module is a solid-state switching device that controls the operation of the ignition coil or coils. It is a small, high-current circuit used to ground the negative side of the coil in order to build charge. In order to fire a spark plug, the engine management system sends a signal to an ignition module which then sends a signal to the ignition coil. This signal tells the coil how long to charge for and when to fire the spark. Ignition Control Modules fail when they overheat.

Ignition control module

.

Misfiring, mistimed ignition or insufficient ignition energy have an essential role to play here. An ignition module, for example, is needed to control this process.

.

Is the engine in your Honda Civic sputtering and failing to start? If so and you've ruled out all possible causes, try testing the ignition control module ICM. It's easy to do and just as easy to replace. The battery is charged as well as properly connected, the spark plugs are firing, and the fuel line is intact. However, your car still won't start, and the engine continues to sputter when you flip the ignition. If you've taken all the diagnostic procedures but none of them have solved the problem, try testing and replacing the ignition control module ICM. This unit relays the signal from the distributor to the spark plugs, and often times, bad grounds, water entering the distributor, or excessive heat may cause the ICM to become faulty. Find the source of that glaring check engine light with this helpful article.

Ignition control module

At WikiMotors, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

Meb sınav ücretleri 2019

Safety The primary current for the ignition coil can be 10 A or more. A slotted disc made from iron rotates between sensor and permanent magnet. The function is relatively straightforward. There are various different sensors: Inductive sensor pick-up : Inside this sensor there is a small coil past which a permanent magnet moves movement generated by the rotation of the camshaft. Note: Please only ever swap modules with matching reference numbers one for the other. Ignition Components Playlist. If the switch is opened again at this point, no more current can flow via the primary winding. A precise square-wave signal is thus generated at the sensor. Otherwise, contact resistances can cause malfunctions or even cable fires. This signal is used to control the ignition module.

The ignition control module is a critical component of the ignition system in an internal combustion engine. It plays a key role in controlling the timing and duration of spark plug firing, which is crucial for proper engine operation. In this article, we will delve into the details of ignition control modules, including their function, importance, and maintenance, to better understand their role in ensuring optimal engine performance.

The ignition coil has a primary winding small number of turns and a secondary winding lots of turns. In older vehicles, this switch was a mechanical contact activated via a "nose" on the camshaft break contact. The energy can thus flow via the spark plug, generating a spark the spark being generated when the switch is opened. If the primary winding of the ignition coil is connected to the in-car 12 V battery voltage via a switch, a current will flow through the primary winding, creating a magnetic field in the ignition coil that acts on the secondary winding. If the switch is opened again at this point, no more current can flow via the primary winding. A slotted disc made from iron rotates between sensor and permanent magnet. It is a small, high-current circuit used to ground the negative side of the coil in order to build charge. In order to fire a spark plug, the engine management system sends a signal to an ignition module which then sends a signal to the ignition coil. Otherwise, contact resistances can cause malfunctions or even cable fires. Hall sensor: This sensor contains an electronic switch which reacts to magnetic fields. A failing module may give other symptoms, such as engine stuttering and stalling, before it stops working. The slotted disc either lets the magnetic field of the permanent magnet through to the sensor or blocks it. One of the components inside an ignition module is a transistor, which takes over the function of the switch. This signal tells the coil how long to charge for and when to fire the spark. Ignition Control Modules Image: Standard LX The ignition control module is a solid-state switching device that controls the operation of the ignition coil or coils.

0 thoughts on “Ignition control module”