Inventor composite to solid

I know there are numerous discussions of this so I apologize but I can't seem to find a helpful solution.

I guess I am not the only person in the world who received 3D models which are not created in Autodesk products. Many times in these cases the model is far from optimal. It consists of huge number of 3D faces or surfaces. This causes huge problems, the 3D model itself will became huge. Even maneuvering in the model will be painfully slow. Not to mention the 2D view generation for orthographic drawings.

Inventor composite to solid

I have a composite part, it must of been an assembly before it was imported into Inventor. It's a control unit for a wireless device basically a box with an antenna. I only want the antenna; it has a rather complicated shape that I need to duplicate. I don't need the "guts" just the exterior. I remember how to do this in SolidWorks but can figure it out in Inventor. I basically want to "hack off" everything but the antenna which I will then reattach normal to the front of the box changing its orientation. I've added 2 screen shots of the box. Also, I have tried deriving it and using the shrinkwrap feature, but no luck. Appreciate any help. Kind of stuck on this one. The best option would be to obtain the native format assembly, but that looks unlikely in this situation. If you can, Inventor will open other format assemblies, and then you will have the option to delete unneeded components.

Message 2 of

.

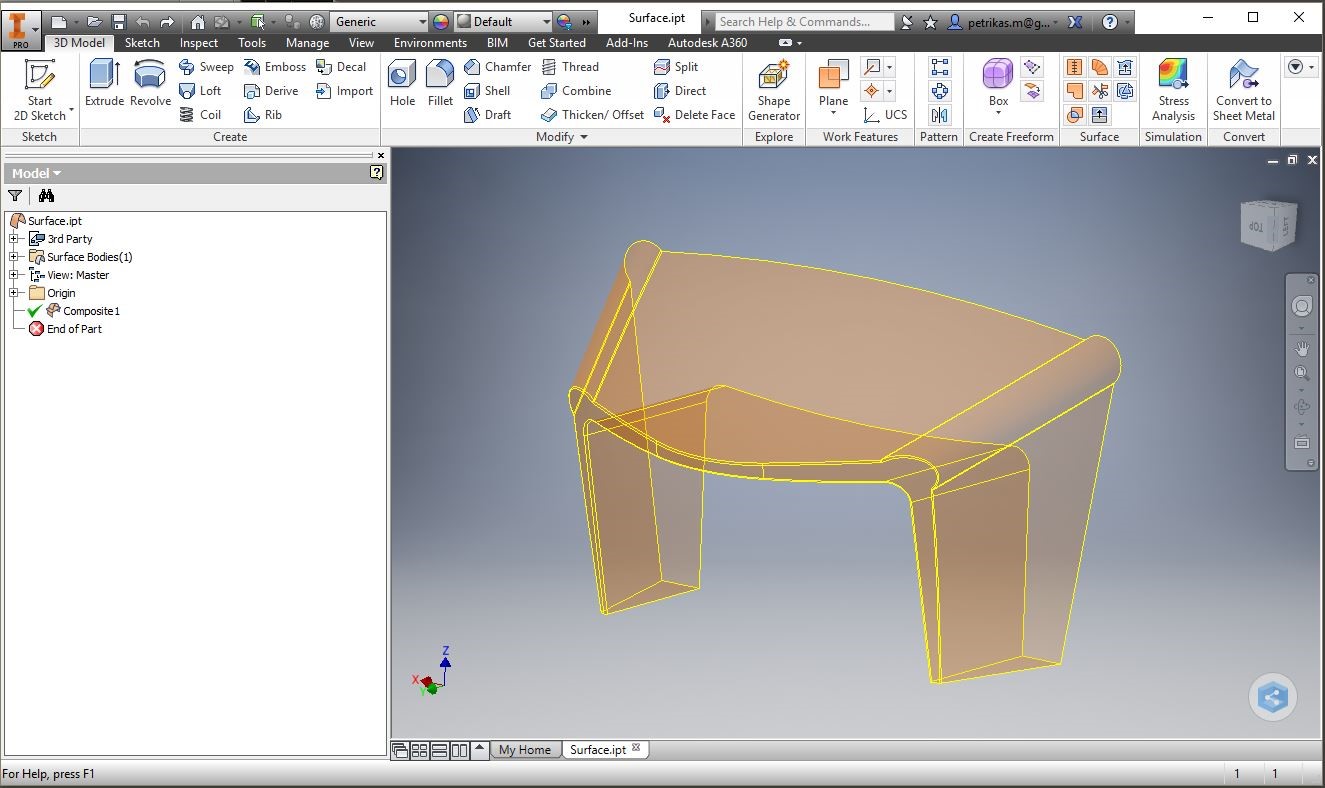

I need some help converting a Composite Part to Solid Part. I have tried using the Thickness Feature but the part still shows up as a composite when i create a shrink wrap or substitute file. I have attached the file for anyone to have a go at it and let me know how you did it. Go to Solution. Solved by blandb.

Inventor composite to solid

You can copy or move geometry within a part file to composites, base surfaces, a repair body or a group in the construction environment. What's New: , When editing a part file within the assembly, you can copy geometry from one part to another, associatively, as a surface or composite feature. These features update automatically when updates are made to the original source data.

Quest diagnostics mount morris

I have a composite part, it must of been an assembly before it was imported into Inventor. Then you select the faces or body to delete. Turn on suggestions. SAF Technology. Origin One. If all you can get is the composite then I think Inventor Fusion will work the best for what you are trying to do. Can you Attach example files that illustrate this workflow? Show only Search instead for. What I found as the best workflow is the following: open the. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

I apologise in advance for how basic this request may be to someone, but i have imported a file into Inventor and it has imported as a Composite. I am not too familiar with Stich and Repair functions so I'm not sure about how to approach this.

T hanks!!!! Back to Inventor Category. Message 9 of Engineering Managers. Leave this field empty. The process can be tedious. I don't need the "guts" just the exterior. Then you select the faces or body to delete. This is not an official translation and may contain errors and inaccurate translations. Advanced PolyJet.

It agree, it is a remarkable piece