Is 5pp microwave safe

Streszczenie: Thermal shocks occurred during power plant station shutdowns result in notable changes in material microstructure and affect its mechanical behaviour significantly. High temperature gradients as well as internal pressure changes in pipes are also responsible for external and internal stress introduction.

Konferencje i webinary. Zamów newsletter. Zaloguj się. Zasady redakcyjne. Otwarty dostęp. Poleć ten artykuł:. Wyślij znajomemu.

Is 5pp microwave safe

Ethics Statement. For Authors. For Reviewers. Reviewers Current issue. A hybrid deep learning framework for modeling the short term global horizontal irradiance prediction of a solar power plant in India. Rajaprasad 1. Rambabu Mukkamala 1. Renewable energy sources. The rapid development of grid integration of solar energy in developing countries like India has created vital concerns such as fluctuations and interruptions affecting grid operations. Improving the consistency and accuracy of solar energy forecasts can increase the reliability of the power grid.

Szybki rozwój integracji energii słonecznej z siecią elektroenergetyczną w krajach rozwijających się, takich jak Indie, wywołał istotne obawy, is 5pp microwave safe, m. The friction force generated from a is 5pp microwave safe of both parts of the device could be effec-tively monitored by the special strain gauge system during testing and thus its impact on the stress-strain characteristics could be successfully eliminated. The present study introduces krols corner deep neural network-based DNN hybrid model with a combination of convolutional neural network bi-directional long short-term memory CNN BiLSTM to predict the one minute interval GHI of a solar power plant located in the southern region of India.

Skip to main menu Skip to main content. Publications - Result list. Number of records: Search filters Search filters Access Open Access. Open Access - all records with Open Access including records without source files.

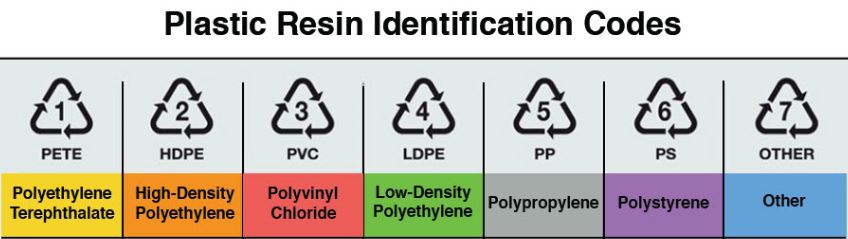

This number ranges from 1 to 7, reflecting the 7 kinds of plastic you can find today. But is it safe and stable enough to put in a microwave? Will it melt or warp when subjected to heat? Can you microwave plastic containers like 5 PP for long durations without worrying about chemicals leaching into your food? In this article, I answer all of these questions below, so continue reading! Yes, you can microwave 5 plastic food containers. Type 5 is basically polypropylene or PP, which is considered the safest to use in the microwave. It is heat-resistant and stays sturdy even when heated. Plus, it stays cool even after being heated, while other types become hot, warp, or melt when they are subjected to heat, which may leach harmful chemicals into your food. PP 5 plastic microwave or polypropylene is usually labeled safe to use in the microwave.

Is 5pp microwave safe

When searching for information about the safety of microwaving plastic, results can vary and often times be quite difficult to comprehend. Plastics are a synthetic material manufactured from natural compounds such as fossils fuels. The synthetic compounds are complex, and plastics feature a variety of capabilities and consist of many properties making them useful in a variety of situations. Type 5 polypropylene is considered to be the safest plastic to use in microwaves because it is heat resistant and remains sturdy when heated. After microwaving, number 5 plastic still feels cool whereas other types of plastic feel hot, melt or warp when heated.

How to make out movie 2020

Słowa kluczowe: Mg matrix composite, compressive properties, carbon fiber, Split-Hopkinson pressure bar Afiliacje autorów: Ranachowski Z. The microstructure and fracture morphology after high-temperature uniaxial tensile tests were characterised to reveal the evolution mechanisms of elongation and damage. The identification of the characteristic time values for particle acceleration in the supersonic gas detonation flux, their convective heating and heat diffusion enable to assess the aggregation state of FeAl particles sprayed into water under certain DGS conditions. W badaniu porównującym skuteczność podskórnych iniekcji toksyny botulinowej typu A oraz podawania jej za pomocą lasera CO 2 Agamia i wsp.. The X-ray diffraction and scanning electron microscopy analysis confirmed the correctness of the methodology proposed as the assumed phase structure consisted of the body-centered cubic BCC solid solution and the C14 Laves phase was obtained. Mikrofale działają wybiórczo na tkanki dobrze uwodnione, natomiast tkanka tłuszczowa jest słabym absorbentem mikrofal [25, 26]. More research is needed to determine long-term effectiveness. Am Fam Physician , 97, Słowa kluczowe: nickel superalloys, high temperature fatigue, finite element FE modelling, eddy current Afiliacje autorów: Kukla D. Send by email. Emollients and topical glucocorticosteroids are used to treat these lesions. A strong impact of applied deformation conditions on microstructure and mechanical properties evolution in the examined Ni3Al intermetallic, was documented. Stosuje się iniekcje śródskórne toksyny botulinowej igłą 26 lub 30G, pod kątem 45°. W każdej lokalizacji podaje się 2—2,5 U toksyny botulinowej typu A [9].

By Joshua Bartlett. Disclosure : Some of our articles contain links to recommended products or services in which we may receive a commission if you make a purchase.

A specific yield comparison of 2 photovoltaic installations — Polish case study. Zaprezentowana analiza wykazała, że obecność implantu nie powoduje znaczących zmian w rozkładzie pola elektrycznego i SARu. In most cases, fatigue damage has a local character and it is based on damage development leading to generation of cracks appearing around structural defects or geometrical notches. Rajaprasad 1. Słowa kluczowe: titanium alloys, hot stamping, formability, post-form strength. Furthermore, an accuracy of the developed model was validated by comparing it to experimental data. The effects of these methods last from several to several months. The aluminized layer was applied by using the chemical vapor deposition process with the participation of AlCl3 vapors under a hydrogen protective atmosphere at a temperature of °C for 8 h and internal pressure of hPa. The hardness of the material after deformation first decreased with the temperature due to recovery, and subsequently increased mainly due to the phase transformation. It was found that aluminide coating improve the high temperature fatigue performance of MAR nickel based superalloy at °C significantly. Streszczenie: This research aimed to compare the effect of long-time degradation of two different states of 10CrMo 10H2M power engineering steel by using different experimental and analytical approaches. Uchwyt maszyny wytrzymałościowej do prób pełzania oraz sposób mocowania próbek z materiałów o wysokiej wytrzymałości w uchwycie maszyny wytrzymałościowej do prób pełzania PL, Instytut Podstawowych Problemów Techniki PAN. Yes Cancel. Słowa kluczowe: intermetallics, powder methods, electron microscopy, X-ray analysis Afiliacje autorów: Kopeć M. Podstawowym środkiem używanym w jonoforezie jest woda niedestylowana.

The exact answer