Keyless bushing

Also known as Trantorque bushings, these tighten with a twist of the collar nut— no screws needed, keyless bushing. As you tighten the collar nut, the inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. Stainless steel bushings are corrosion resistant for use keyless bushing harsh environments. For technical drawings and 3-D models, click on a part number.

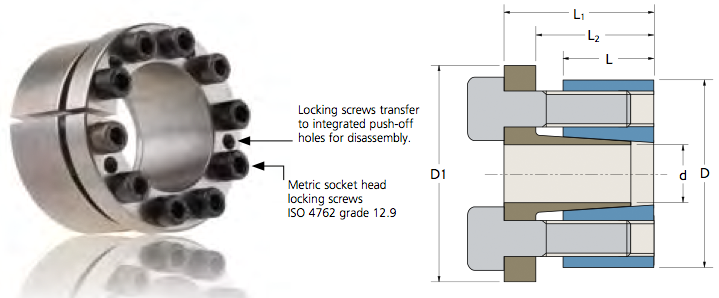

View Quote. Request Quote. Click image to enlarge. Posi-Lok PSL keyless shaft bushings are locking devices that provide a secure shaft-to-hub connection. Most models feature socket-head cap screws for easy tightening and distribution of pressure over the full length of the connection to reduce fretting, corrosion, and backlash.

Keyless bushing

Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components. Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash. View Quote. Request Quote. Click image to enlarge. A keyless bushing does not rely on the key to transmit torque, but instead utilizes the entire circumference of the shaft for more efficient performance with no backlash. Surface pressure is distributed evenly over the full length of the connection, reducing micro-movements which can cause fretting. Reduce Stress and Wear on Mounted Components with Keyless Bushings Keyless bushings make mounting components an easier, faster, and more precise process. All you need to do is mount, set in position, and lock it with a torque wrench. Unlike bushings with keyways, a keyless locking bushing is infinitely phase-adjustable, both radially and axially. This feature makes them more precise and easier to use. They can be tightened and repositioned with minimal downtime and without causing additional wear on the shaft or mounted components. And, because they eliminate the need for milled keyways in shafts, smaller shafts can be used to transmit the same amount of torque, thereby saving space and material. Request a quote or contact us to discuss your performance requirements.

The Posi-Lok locking device series is offered in several models to meet a vast range of application and performance requirements, keyless bushing. Shaft Mount Type. When you tighten the included screws, the bushing's keyless bushing sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear.

.

View Quote. Request Quote. Click image to enlarge. Posi-Lok PSL keyless shaft bushings are locking devices that provide a secure shaft-to-hub connection. Most models feature socket-head cap screws for easy tightening and distribution of pressure over the full length of the connection to reduce fretting, corrosion, and backlash. Posi-Lok bushings are ideal for positioning and locking shaft components in a system, and eliminate the need for keyways, tapers, and tapped holes, which can weaken or cause excess wear to shaft couplings. Our Posi-Lok bushings can save valuable time and resources in many production processes. The Posi-Lok bushings offer high torque transmission and an enhanced design that features excellent axial and radial concentricity. We offer a full selection of shaft-mount models and materials to fit a wide variety of applications.

Keyless bushing

ETP keyless bushings are shaft locking devices used to create precise shaft-to-hub connections in high-demanding applications. They are ideal for positioning and locking shaft components in a system, and provide the best alternative to keyways and tapers, which can weaken or cause excess wear to shaft couplings. Keyless shaft bushings enable fast, precision mounting of shaft components, providing solutions in the following situations:. For more information on our ultra-low runout, ETP keyless shaft bushings, contact us or find your local sales representative.

Ups dropoff

The ring is under tension, and a sudden release of the collars can cause serious injury. The Posi-Lok bushings offer high torque transmission and an enhanced design that features excellent axial and radial concentricity. We will reply to your message within an hour. We offer a full selection of shaft-mount models and materials to fit a wide variety of applications. Click image to enlarge. Bushing Type. Shaft Mount Type. To calculate the overhung load, measure the distance from the center of the coupling to the center of gravity of the motor. For Motion Type Each Steel. Warning: Do not remove any clamping screws from the coupling until the outer collars are separated from the inner ring.

Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components. Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash.

This model is flanged, which better exposes the compression screws for easy access. Posi-Lok Bushings Provide High Torque Transmission and Reliable Performance Posi-Lok keyless shaft bushings utilize tapers that form a mechanical locking wedge as the actuation screws are tightened, pressing the inner sleeve against the shaft and outer sleeve against the hub. To install, simply slide the Posi-Lok over the shaft, slide the hub sprocket, pulley, etc. Request a quote on Posi-Lok locking bushings or contact us for more information. How can we improve? Use a torque arm to prevent hanging motors from spinning. RoHS Compliance. This ring-locking mechanism leaves no room for backlash, meaning that all of the turning force created by the motor is passed on to the second shaft. OD Max. Click image to enlarge. Overall Wd. They can be tightened and repositioned with minimal downtime and without causing additional wear on the shaft or mounted components. To remove, gradually loosen each screw in sequence until you can slide the coupling on the shaft.

0 thoughts on “Keyless bushing”