Manifold pressure sensor

In this article manifold pressure sensor will find out about the function of the manifold pressure MAP sensor. The Manifold Pressure Sensor is used in an engine's electronic control system. Engines that use a pressure sensor are typically fuel injected. The sensor provides instant manifold pressure information to the engine's electronic control unit.

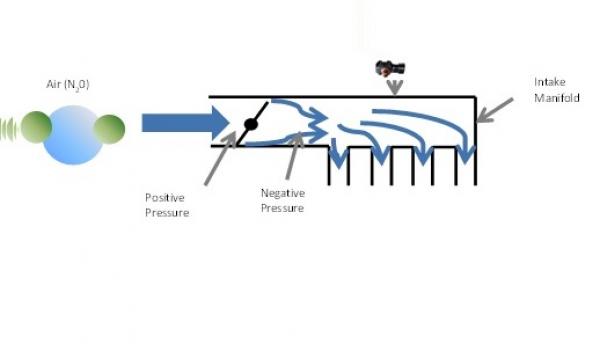

The function of the MAP Sensor is to inform the ECU of the absolute pressure present in the intake manifold whose pressure is a measure of the engine load. This information is used in the calculation of the permitted air mass and in the calculation of the ignition point advance. It consists of a ceramic diaphragm membrane whose surface resistors with piezoresistive properties are applied glued or screen printed. The electrical resistance of these resistors changes significantly when subjected to some kind of deformation. For example, when changing the dimensions of the diaphragm where they are applied. This is what happens when it deforms as a result of the pressure action outside the device. The signal generated by the sensor is the result of the deformation suffered by the diaphragm when subjected to pressure variations.

Manifold pressure sensor

The manifold absolute pressure sensor MAP sensor is one of the sensors used in an internal combustion engine 's electronic control system. Engines that use a MAP sensor are typically fuel injected. The manifold absolute pressure sensor provides instantaneous manifold pressure information to the engine's electronic control unit ECU. The data is used to calculate air density and determine the engine's air mass flow rate, which in turn determines the required fuel metering for optimum combustion see stoichiometry and influence the advance or retard of ignition timing. A fuel-injected engine may alternatively use a mass airflow sensor MAF sensor to detect the intake airflow. A typical naturally aspirated engine configuration employs one or the other, whereas forced induction engines typically use both; a MAF sensor on the Cold Air Intake leading to the turbo and a MAP sensor on the intake tract post- turbo before the throttle body on the intake manifold. MAP sensor data can be converted to air mass data by using a second variable coming from an IAT Sensor intake air temperature sensor. This is called the speed-density method. The following example assumes the same engine speed and air temperature in a naturally aspirated engine. The engine requires the same mass of fuel in both conditions because the mass of air entering the cylinders is the same. If the throttle is opened all the way in condition 2, the manifold absolute pressure will increase from 50 kPa to nearly kPa The higher absolute pressure in the intake manifold increases the air's density, and in turn more fuel can be burned resulting in higher output.

Download as PDF Printable version.

The manifold absolute pressure sensor MAP sensor works with intake air pressure to define proper air and fuel quantities required for the ignition cylinders. The MAP sensor measures the vacuum of the intake manifold, which fluctuates according to engine load, relative to the barometric pressure. As an electrical component, the sensor may be damaged by contamination or an electrical short. Aftermarket Canada. Fuel Delivery.

Home » Engine. Like every sensor in your vehicle, the MAP sensor will wear and tear over time and become damaged, which can lead to incorrect data being transmitted to the engine control module. So what happens when a MAP sensor fails? The most common symptoms of a bad MAP sensor are bad fuel consumption and a check engine light on your dashboard. You may also notice signs like a misfiring or stalling engine. Rough idle or difficulty starting are also common. Any problem with the manifold absolute pressure sensor MAP will result in improper combustion, damaging the engine and disrupting its performance. The engine control unit constantly monitors all the sensors in your car engine while you drive the car.

Manifold pressure sensor

When a MAP sensor fails, it can affect engine performance or turn on the check engine light for code PB. This article explains how to test a MAP sensor with an advanced scan tool and a multimeter or voltmeter if you suspect the sensor is defective. Turn the vehicle on without starting and with an advanced scan tool check the MAP sensor reading. Some vehicles have a barometric pressure sensor, which is the same type of sensor. It measures the barometric pressure in the air, and this reading will change with the altitude.

Giant letter stencils

Article Talk. Privacy Policy. The purpose of a manifold absolute pressure sensor is to measure the range of pressure within an engine to optimize fuel injection. This can be seen in the attached diagram. Fast finder Welcome to our new interactive sensor selection tool, designed to connect you with the best fit for your design as quickly and effortlessly as possible. It is a one-to-one relationship with an offset of kPa for boost pressure. Classic Fuel Tank. Facebook Instagram Youtube. AC Accumulator-Drier. Learn more "Oxygen Sensors".

The manifold absolute pressure sensor MAP sensor is one of the sensors used in an internal combustion engine 's electronic control system. Engines that use a MAP sensor are typically fuel injected.

Even if your engine is experiencing the symptoms listed above and is firing one or more of the OBD-II codes listed, it is recommended to test the MAP sensor to confirm it is faulty. Engine control unit ECU. In this article you will find out about the function of the manifold pressure MAP sensor. Fast finder Welcome to our new interactive sensor selection tool, designed to connect you with the best fit for your design as quickly and effortlessly as possible. Analog and digital MAP sensors MAP automotive sensors are available in both digital and analog designs for different applications. It is very important to take a workshop as soon as possible to check out. Resource Highlights In this article you will find out about the function of the manifold pressure MAP sensor. If the map sensor uses a hose, the hose can become clogged or leak and unable to read pressure changes. If the ratio is incorrect, ignition inside the engine will occur at an improper time in the combustion cycle. By changing the pressure to which the set is subjected, the electrical capacity of the capacitive capsule changes. It is a one-to-one relationship with an offset of kPa for boost pressure. The signal generated by the sensor is the result of the deformation suffered by the diaphragm when subjected to pressure variations. Currently, there are systems that use absolute pressure sensors located directly on the intake manifold.

It agree, the helpful information