Marine hdpe board

JavaScript seems to be disabled in your browser.

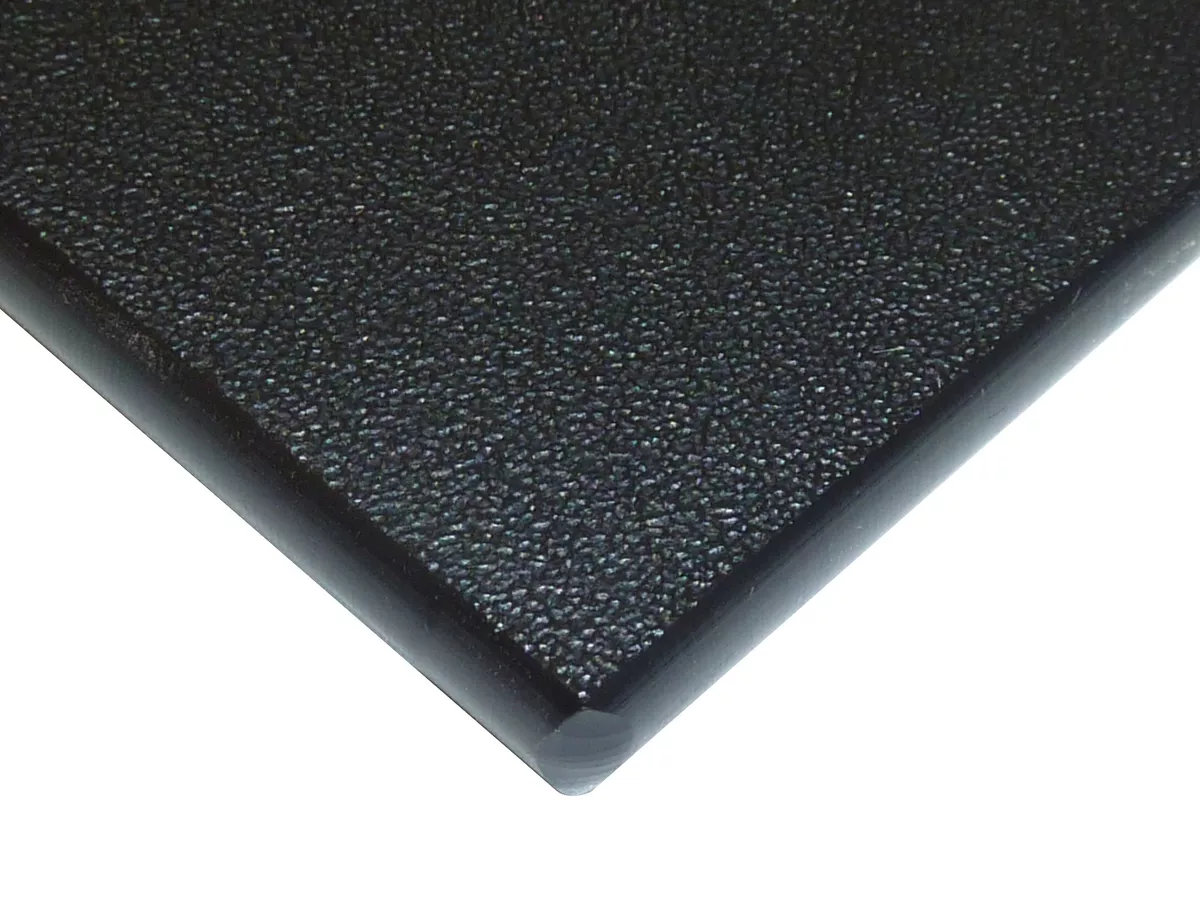

Do you frequently need building materials that you can use in applications where moisture resistance and cost-effectiveness are key? Thermoplastics are incredibly versatile. Best of all, this marine substrate is made to maintain its color and finish for the lifetime of the boat. You can use table saws, drills, blades, and bits with our polyethylene sheets. It will not warp, rot, or delaminate when exposed to humidity or water.

Marine hdpe board

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Clear Polycarbonate. Colored Polycarbonate. Abrasion Resistant Polycarbonate. UV-Resistant Polycarbonate. Twinwall Polycarbonate. ABS Plastic. Polyvinyl Chloride PVC. Corrugated Plastic. Engineered Plastic. Drill Bit. Saw Blade. Silicone Sealants. High-performance material that is tough, impact-resistant, virtually unbreakable, and can be used in many applications due to its dimensional stability and electrical properties.

Only 1 left in stock - order soon. Current Stock:. For the best experience on our site, be sure to turn on Javascript in your browser.

For large or custom orders, click the add to quote button to put together a custom order request. Maintenance-free integral colors. Long-term durability for boat building components, outdoor and indoor cabinetry. In boat building components, this tough, UV resistant sheet withstands long term exposure to intense sun, salt water and rigorous use. This also makes it ideal for outdoor patio, poolside and marina cabinetry, furniture and accessories. Its impact resistance, FDA compliance, easy-to-clean surface and attractive appearance enhance indoor medical, clinical and laboratory cabinetry as well. Its stain resistance, easy-to-clean matte finish and wide spectrum of integral colors further assure long lasting appearance and functionality.

Do you frequently need building materials that you can use in applications where moisture resistance and cost-effectiveness are key? Thermoplastics are incredibly versatile. Best of all, this marine substrate is made to maintain its color and finish for the lifetime of the boat. You can use table saws, drills, blades, and bits with our polyethylene sheets. It will not warp, rot, or delaminate when exposed to humidity or water. Click Here for specifications on Deflection. It is the buyer's responsibility to ensure the suitability of this material for use in individual applications. We highly recommend material sampling be done in support of any material selection criteria.

Marine hdpe board

It is environmentally stabilized to withstand the harshest outdoor conditions. It is ideal for a variety of marine applications from replacing wood, to building boat components and furniture. The polymer sheet never needs painting or refinishing, works like wood, and is easy to fabricate with common woodworking tools and techniques. This product is exempt from registration under 40 CFR

22r starter relay

Well packaged. Should I replace the wood trim on my boat with superior custom marine plastics? How customer reviews and ratings work Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. Visit your local TAP Plastics store where cut-to-size orders often take less than five minutes, start to finish. Other Sellers on Amazon. This also makes it ideal for outdoor patio, poolside and marina cabinetry, furniture and accessories. We found other products you might like! No painting or refinishing is ever needed. HDPE Smooth. Deals and Shenanigans.

.

Configure Delete. Typically, sealants are used to close small openings that are difficult to eliminate through other processes or materials. King StarBoard was the first of its kind on the market and TAP Plastics is proud to bring you the highest quality marine polymer sheets for a vast array of applications. Get it as soon as Thursday, Feb Next page. Our highly trained experts can promptly provide a quote for any cut-to-size request. Help others learn more about this product by uploading a video! Has passed the Federal Motor Vehicle Standard fire test required for use in motor vehicles, including motorhomes. Cut-to-size requests may take one to two business days to process, or you can visit one of our store locations to get custom HDPE plastic sheets in five minutes or less from start to finish. Ships from. Be sure to wear a mask when cutting or drilling.

I apologise, but, in my opinion, you are not right. I am assured. I can defend the position. Write to me in PM, we will talk.

In my opinion you are not right. I am assured. Let's discuss it.

Improbably!