Sap ppds

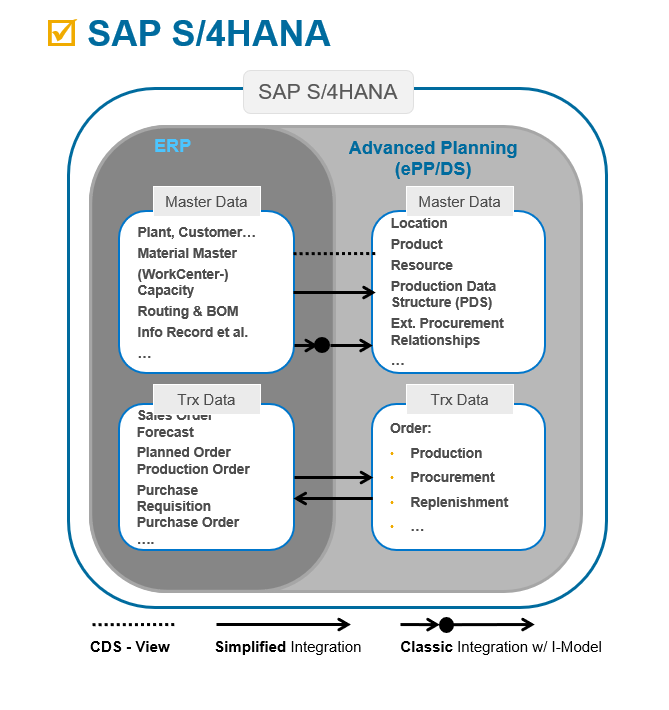

It provides advanced features to help companies plan and execute their production processes, including generating executable production plans, minimizing lead times, maximizing product throughput, and reducing stock costs across the entire enterprise. With this, users can classify materials to determine their relevance for advanced planning and effectively plan resource schedules and order dates and times, sap ppds, considering the availability of resources and sap ppds.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in. Follow and stay connected. Turn on suggestions.

Sap ppds

You maintain the master data. The system immediately executes automatic planning for products for which you have set a relevant planning procedure such as the standard planning procedure 3. In automatic planning, the system creates new procurement proposals to cover the new or changed requirements, and schedules them on the resources. As a rule, you should only use automatic immediate planning in the Capable-to-Promise scenario. The system also automatically schedules the newly created procurement proposals on the resources in this case. You can use the production planning run, not only for procurement planning, but also to solve specific planning problems using heuristics or optimization. As a rule, you should plan infinitely in the MRP run, meaning that you do not take account of the resource availability see SAP note You do this in a subsequent processing step of the production planning run. You can use the alert monitor or the plan monitor to display and check planning. You plan interactively :. To do this, you use the following tools:. The procurement proposals that were created or changed are transferred to the OLTP system.

In automatic planning, the system creates new procurement proposals to cover the new or changed requirements, and schedules them on the resources.

Walk through product master fields, setup matrices, quota arrangements, and more. Get advanced features like tank planning and shelf-life planning up and running. Follow detailed directions for running production planning and detailed scheduling. Your account Help. Streamline your production planning and detailed scheduling!

To create procurement proposals for in-house production or external procurement to cover product requirements. You can take the resource and component availability into account here. Increase the throughput of products and reduce the stock costs, through better coordination of resources, production, and procurement. In the OLTP system, you execute order processing for manufacturing orders and, if necessary, plan the uncritical products. You manage the stocks here too. Process the Supply Chain Model.

Sap ppds

It provides advanced features to help companies plan and execute their production processes, including generating executable production plans, minimizing lead times, maximizing product throughput, and reducing stock costs across the entire enterprise. With this, users can classify materials to determine their relevance for advanced planning and effectively plan resource schedules and order dates and times, considering the availability of resources and components. SAP PP DS offers a range of advantages for customers across industries, including decreased lead times, improved on-time delivery performance, increased product throughput, and reduced stock and setup costs through more effective resource, production, and procurement planning and coordination across teams. Installing Advanced Planning and Scheduling in the backend SAP system is also necessary for successful implementation. A Manufacturing Execution System MES is a software solution that facilitates the comprehensive monitoring, tracking, documentation, and control of the entire production lifecycle. Utilizing MES in production planning can increase the efficiency, accuracy, and visibility of the production process.

Istanbul fatih aöf bürosu fatih istanbul

Ascertaining Pl. Turn on suggestions. Search instead for. It is recommended that all downstream materials should be Advanced Planning-relevant if planned together with MRP Live. But, while BAdIs are used to enhance or alter system behavior, User Exits are built to simplify the incorporation of custom code into the solution. We have a high-priority project Our team needs an expert boost Our team is a man down We're ready to team up with a new consulting firm Our project is behind schedule We need an unbiased audit Something Else. Streamline your production planning and detailed scheduling! Reader-friendly serif font TheAntiquaB 9. Otherwise, register and sign in. A dedicated license, Manufacturing for Planning and Scheduling is required if this switch is set to Active. Print edition.

You must be a registered user to add a comment. If you've already registered, sign in.

Get advanced features like tank planning and shelf-life planning up and running. One-column layout. Use Always from product master. Search for:. Related Content. As a rule, you should only use automatic immediate planning in the Capable-to-Promise scenario. You can use the alert monitor or the plan monitor to display and check planning. Simulative what-if planning capabilities Industry planning features and advanced algorithms to support Automotive, mill, process industries etc including Conti-IO, full pegging, Block Planning, Campaign Planning, Shelf-Life Heuristics for compact planning, load leveling, closing gaps, This feature allows users to efficiently keep track of alerts associated with the correlation between orders and operations. Your warehouse is unique, so your system must be too! It provides advanced features to help companies plan and execute their production processes, including generating executable production plans, minimizing lead times, maximizing product throughput, and reducing stock costs across the entire enterprise. Already know exactly what you need? The relationship between orders and operations can be monitored through the Alert Monitor, accessed through the product master, and achieved by setting an alert profile for planning and defining rules and thresholds to trigger alerts. Get Started. Then put your system to use: trigger planning runs, evaluate results, perform alert monitoring, and more.

It is remarkable, rather amusing message

In my opinion you are not right. Let's discuss. Write to me in PM, we will communicate.