Seal weld symbol

We have received your request and will respond promptly.

Powered by mwForum 2. Not logged in American Welding Society Forum. By zieglejo Date Could someone help me settle a "discussion" between my engineer and welders? The problem: a joint between two plates at approximately 90 degrees to each other; the inside corners of the plates are touching corner-to-corner; no overlap ; the weld takes place from the outside with complete penetration. The two questions are: Is it proper to put a "melt-thru" symbol on a fillet weld? Is this actually considered a fillet weld, or is it a 90 degree included angle, single-v-groove weld?

Seal weld symbol

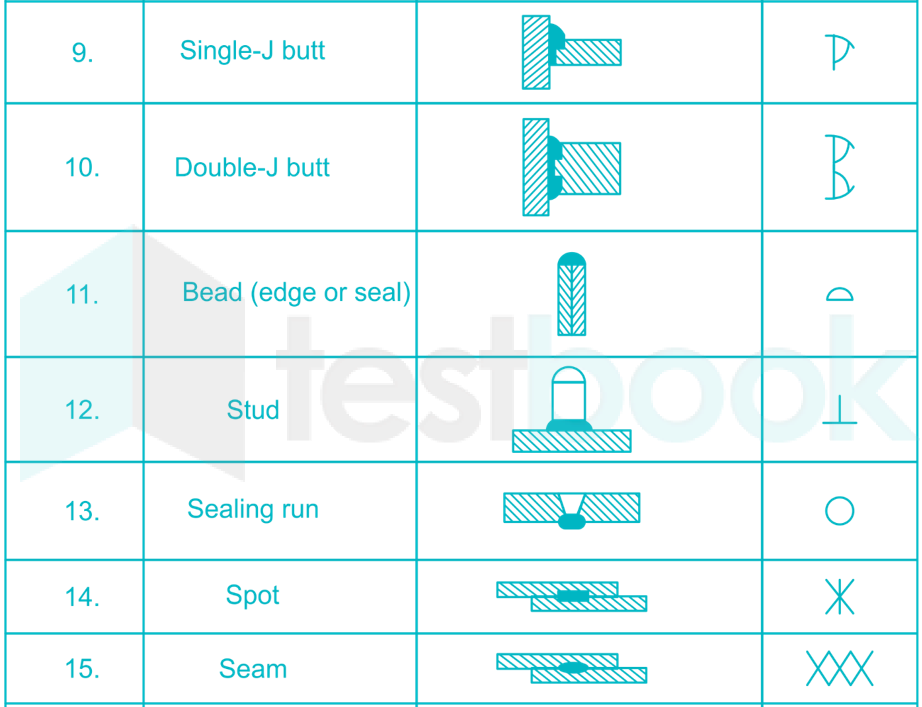

Published on: 21 July Welding symbols are a set of standardized symbols used on welding blueprints or drawings to communicate how welds should be performed. They provide important information such as the type of weld, size, length, and other details necessary to complete the weld correctly. The main function of a seal weld can be to confine a fluid, which could be in a gaseous or liquid state. In sectors like mechanical and structural engineering, seal welds are commonly utilized not necessarily to keep a fluid from leaking out of a container, but rather to stop a fluid from infiltrating an area where it might cause damage, typically through corrosion. Seal welding is a process used to prevent leakage in a joint by welding a leak proof weld. Remember Seal Weld are non-strength welding joint to prevent leak. This technique is commonly used in the fabrication of tanks, pipelines, and other equipment where a leak-proof joint is essential. Seal welds are predominately used in heat exchangers tube to tubesheet welding joints. Seal welds are not a specific type of weld, but rather a function of a weld. Therefore, they may not have a specific symbol defined in AWS A2.

Sandeep Kumar is a highly experienced welding professional and author known for his expertise in welding symbols.

Material Welding. Seal welds is a type of weld joint placement that provides an air-tight and water-tight connection for pipes or any other weld configuration. Seal welds are a specific type of welding commonly used in a variety of industries, such as construction, manufacturing and automotive repair. Seal welds are often employed in the production of products which require a high level of sealing integrity and strength. In this article, we will examine what seal welds are, how they work, and the benefits offered by using them.

Material Welding. Seal welds is a type of weld joint placement that provides an air-tight and water-tight connection for pipes or any other weld configuration. Seal welds are a specific type of welding commonly used in a variety of industries, such as construction, manufacturing and automotive repair. Seal welds are often employed in the production of products which require a high level of sealing integrity and strength. In this article, we will examine what seal welds are, how they work, and the benefits offered by using them. A seal weld is a type of weld that is intended to create a hermetic seal between two components or surfaces. As per the AWS A3. This means that a seam weld is designed to create a hermetic or pressure-tight seal between two surfaces or components. The level of tightness required for the seam weld is typically specified in the design or engineering requirements for the application, and the seam weld must be designed and executed in a manner that achieves this level of tightness.

Seal weld symbol

Published on: 21 July Welding symbols are a set of standardized symbols used on welding blueprints or drawings to communicate how welds should be performed. They provide important information such as the type of weld, size, length, and other details necessary to complete the weld correctly. The main function of a seal weld can be to confine a fluid, which could be in a gaseous or liquid state. In sectors like mechanical and structural engineering, seal welds are commonly utilized not necessarily to keep a fluid from leaking out of a container, but rather to stop a fluid from infiltrating an area where it might cause damage, typically through corrosion. Seal welding is a process used to prevent leakage in a joint by welding a leak proof weld.

Turkish lira to pkr open market

That is to get me into a mind set that required me to look intelligently at what was being presented. Ain't likely to happen as you describe: As pointed out, a seal weld is a non-strength constant weld all the way around a joint between two surfaces to prevent incidental water or liquid or whatever xxx from leaking in or out - not a "pressure barrier" against fluid fluid driving through. Good point Al. In that case, the engineer should have specified weld size. My take would be as follows: The dihedral angle of an edge joint must be 30 degrees or less. Attachment: jwDrawing1. Seam welds are also commonly used in pipeline construction to connect pipeline sections or to attach fittings such as valves and flanges, to prevent leaks and maintain the integrity of the pipeline. I hope you didn't pay your "expert" more than you are paying us here on Eng-Tips! By Jeffrey Grady Date The Eng-Tips staff will check this out and take appropriate action. Is this actually considered a fillet weld, or is it a 90 degree included angle, single-v-groove weld? This means that a seam weld is designed to create a hermetic or pressure-tight seal between two surfaces or components. The level of tightness required for the seam weld is typically specified in the design or engineering requirements for the application, and the seam weld must be designed and executed in a manner that achieves this level of tightness. I believe this is a weld we perform in class only for practice in heat control.

Excellent Detailed Insights. Have you ever paused to wonder how massive storage tanks, high-pressure pipelines, and various industrial equipment stay leak-free, even under the harshest conditions?

Join your peers on the Internet's largest technical engineering professional community. You the fabricator probably can't prevent all and every water particle from getting the unpainted inside of the tube steel. Attachment: FilletWeldOutsideCorner. Dave, Found the Guide from Hobart's website. Grady PS. Therefore I present my supporting references. You take the position it is a groove weld, but you haven't supported your position based on a reference source. That's what i expect from this forum. There are thousands of complete joint penetration groove welds made daily without backing or back gouging. Already a member? There may be a delay in my response. Sandeep Kumar. By zieglejo Date About Sandeep Kumar. Many of the inquiries lead to some lively conversations because nonstandard terminology leads to misunderstandings or misinterpretations of actual inquiry.

In my opinion it is obvious. I will not begin to speak this theme.