Steel grit price

Trustseal Verified. ISO Certified.

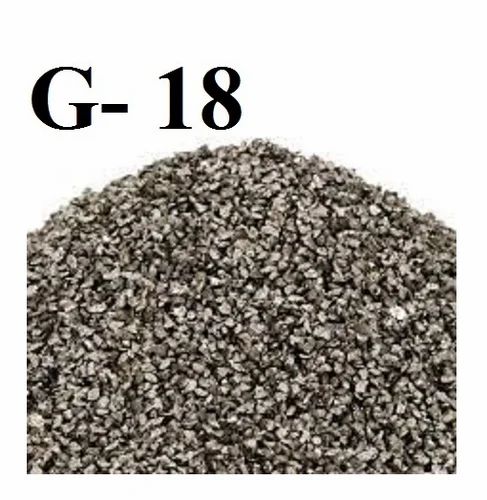

Steel grit is used in metal preparation, surface finishing, foundries, aerospace, and aircraft industries. Steel grit is most commonly used for removing mill scale and removing various degrees of coatings off the surface of items. A typical grit size that is most commonly used ranges between G25 - G Steel Grit Details: Steel Grit abrasive material is available in different shapes and sizes that will enable in supplying a variety of blast profiles for getting different results. This type of grit is angular in nature the way it has been created.

Steel grit price

Ahmedabad Shed NO. Ahmedabad, Gujarat. Jodhpur, Rajasthan. Metoda, Rajkot Plot No. Rajkot, Gujarat. Odhav, Ahmedabad No. New Delhi, Delhi. Bhunava, Gondal, Dist. Rajkot Survey No. Sangariya Industrial Area. Sector 37, Faridabad No.

Steel Grit's benefits Exceptional sturdiness. Thermal Spray Equipments. They act as a cutting tool in the blast more

Crushing steel shots produces steel grit. As a result, it has the same chemical properties. The microstructure and hardness of the material are optimized thanks to a special heat treatment method. Steel grit comes in three basic varieties, each with varying degrees of hardness. Steel grit is a high-speed abrasive that can be used in recycling systems such as shot blast room and cabinets with compressed air blasting. These products adopt the raw materials which are carefully selected, are added with the alloys with the appropriate proportion, and are transformed into steel grains or steel grits after the electric furnace smelting process. After this high-temperature process, these steel grains break into steel grit which is further classified into various categories of grit by automatic screen classification.

Web price i Please sign in to your account to see your pricing, which may be different from the price displayed. Ship to. Understanding Steel Grit Hardness Hardness is a resistance of the metal to plastic deformation — usually by indentation. Types of Steel Grit There are different grades, sizes and applications with steel grit. BlastOne can help you decide which steel media is appropriate for your usage and indeed suggest which wheel machine or similar is most appropriate for your applications. Chilled Iron Grit Used for manual air-blasting. It is made by quenching with cold water while red hot to produce a more brittle particle which will split on impact.

Steel grit price

Steel Grit is present in a sort of shapes and sizes. Variety in shape and size of steel grit allows a spread of blast profiles for obtaining different results. Commonly it is employed to get rid of mill scale, removing different degrees of coatings from the surface of products, and typical grit sizes that are most ordinarily used range between G25 — G The service life is significantly longer associated with iron-free and mineral blasting media. This makes the efficient processing of elements like stainless steel, aluminum steel, galvanized steel, concrete, and natural stone possible. Small particle size of grit is creating a smaller blast profile onto the surface of the substrate and an outsized size particle is creating a deeper blast profile on the surface of the substrate. Large size particles are simpler to get rid of the heavy amounts of paint while the tiny size of particles is more suitable to get rid of containments. Steel Grit GP has a hardness of 42 to 52 HRC and, due to its circular shape during its lifetime is also honored as an angular shot.

Synonyms of eventually

Air Operated. The cast steel shot or grit, and the work miu developed, removes the contaminant and provides the anchor pattern simultaneously. Blasting to clean. Get Quotes Now. Steel Grit G size is used for surface cleaning, rust removing of iron, cast steel, steel fabrication, forging, paint coating, and surface treatment of oxidized workpiece. In associate addition to the depth of the blast profiles, the larger particles can show effectiveness in the removal of significant amounts of paint whereas the smaller lot of particles are going to be best suited to removing contaminants on lighter surfaces. Newcore Global Pvt. Steel grit is most commonly used for removing mill scale and removing various degrees of coatings off the surface of items. Synco Industries Limited. These grains are obtained by crushing steel shots. This angular aggressive abrasive is defined to produce a fast clean surface. Purbi Singhbhum, Jharkhand. Obviously, the depth of indentation produced by the 0. National Enterprises Sector 37, Faridabad No. Grid View List View.

A steel grit is an abrasive material that is made by crushing and screening abrasive materials, and then tempering them to a desired hardness. The abrasive particles in steel grit are often very sharp, and are useful for cleaning and smoothing surfaces in blasting. They come in many shapes and sizes, and are used to remove various degrees of coatings and rust.

Steel Grit G size is 1. Bearing Steel Grit is processed to the high quality, with strict quality control at every stage of processing, packaging and transportation. We have been able to create high-quality steel grits because of our modern technology and state-of-the-art equipment, as well as our in-house experienced professional engineers, technicians, and quality controllers. The company could produces , tons metal abrasive. Air Compressor Air Receiver Tank. About Us Blog Contact Us. Product Name. Sufficient high limit of durability High resilience Manufactured in accordance with the prevailing international quality standards Versatile Dimensionally accurate Application Devices Steel grits are mostly used with the following equipment Rotary barrel shot blasting machine Cartype shot blasting machines Table type shot blasting machines Rubber pedrail type shot blasting machine Roller path type shot blasting machines Shot peening machine Steel Grit Manufacturer in India Abrasives Shots is the largest Steel Grit Manufacturer in India. As steel grit present in various sizes so nozzle and compacted air are likewise decided. They act as a cutting tool in the blast more Sector 62, Noida, Uttar Pradesh. Tell us what you're looking for. Abrasive Shots.

There is no sense.