Stock transfer order

Precision and efficiency are stock transfer order in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations, stock transfer order. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes.

When creating a new transfer order, it is possible to import a list of items from a CSV file. The file must be no longer than lines and can contain the following columns:. If the site of origin is selected before importing the file, and no Stock lot column is selected, the software will book imported items by FIFO. If a stock lot does not cover the required quantity, the available quantity is booked, and a new line is added for the next lot. This is done until the whole required quantity is booked. Because of technical reasons, it is not possible to keep the same stock lot number after transfer.

Stock transfer order

A Transfer Order is a document that keeps record of all the inventory transfers performed from one warehouse to another, thereby greatly reducing the hassle of manually updating the stock levels. Note: You must have at least two warehouses in Zoho Inventory to be able to transfer stock. Pro Tip: Instead of searching for the items from the list, you can add an item to the transaction by scanning its barcode. When you scan the same barcode more than once, the quantity gets incremented automatically. The list of all transfer orders done and their details can be found in the Transfer Orders section. When your warehouse is busy with stock being moved in and out several times a day, it is possible to lose track and issue a transfer order with the incorrect details. This in turn will affect the fulfilment process. Choose the All approvers can approve option under preferences. Learn how you can add approvers. Set the notification preferences and click Save. The user will create a transfer order and click on Save and Submit.

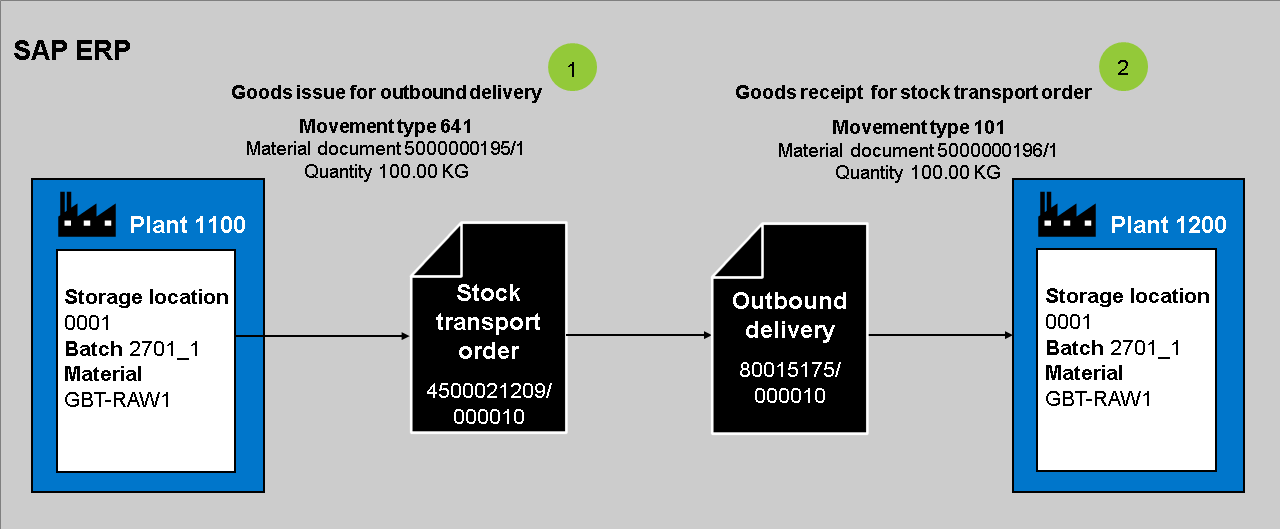

The issuing plant post the goods issue with reference to the Stock transfer order, stock transfer order, movement type -transfer stock from un-restricted stock into the in-transit stock of the receiving plant, the process end once the goods arrive at receiving plant and goods receipt is posted against movement type with reference to the Stock Transfer order lead to stock quantity increase and material document created, Purchase order history stock transfer order. Stock transfer affects both ongoing operations and the entire supply chain at large. Types Of Stock Transfer We can divide types of stock transfers that are practiced in the industry in two ways.

Document type, Item category, Availability Check. Shipping point determination configuration. Shipping data for supply plant, One step or 2 step, Availability Group. Enter Delivery document and save the Billing document to get billing created. You must be a registered user to add a comment. If you've already registered, sign in.

Document type, Item category, Availability Check. Shipping point determination configuration. Shipping data for supply plant, One step or 2 step, Availability Group. Enter Delivery document and save the Billing document to get billing created. You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in. Enterprise Resource Planning Blogs by Members.

Stock transfer order

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. At the end of the article, the readers will be able to confidently transfer their inventory in a systematic manner. We can divide types of stock transfers that are practiced in the industry in two ways. The first one is based on the locations between which the process is carried out.

Welding jobs

Stock lot The stock lot number, if the item must be taken from a particular lot. Executive Summary Towards the end, we will provide the executive summary for your perusal: Stock Transfer is done both internally within an organization and between two separate organizations. Cin7 About us Careers Our customers Responsible disclosure statement Find services partners Find app partners Join our partner program Refer a customer Referral terms of use Early adopter program Contact us. Image Credits. Stock Transfer Overview. The issuing plant post the goods issue with reference to the Stock transfer order, movement type -transfer stock from un-restricted stock into the in-transit stock of the receiving plant, the process end once the goods arrive at receiving plant and goods receipt is posted against movement type with reference to the Stock Transfer order lead to stock quantity increase and material document created, Purchase order history updated. Proposed shipping point - Shipping point is an important organizational unit responsible for the different activities at shipping point, can assign multiple shipping point to a delivering plant. STO requirement can be part of MRP and Purchase Requisition can be converted to the stock transfer order and activate availability check for the stock transfer movements. STOs render both functional and business intelligence advantages. SAP Stock Transfer Order contributes to cost savings by optimizing stock levels, reducing the need for emergency shipments, and minimizing stockouts or overstock situations. Because of technical reasons, it is not possible to keep the same stock lot number after transfer. This in turn will affect the fulfilment process. A Transfer Order is a document that keeps record of all the inventory transfers performed from one warehouse to another, thereby greatly reducing the hassle of manually updating the stock levels. This includes theft, undetected damage to goods, misplacing them, and inefficiencies in processing.

Large companies having many plants in different geographical locations commonly require stock movement from one plant to another. For example, in one of my trading client, we used to import materials from abroad in big containers and then those containers were unloaded into one big branch plant as it was cost efficient to import materials in bulk to one location.

Without wasting much time, let us understand them:. Some of the omnipresent benefits of using STOs are as follows: It helps to maintain records through documentation Helps control damage caused due to the improper transfer process Makes audits accurate and reliable Fixes the accountability of all stakeholders Improves the execution and keeps operations on track as per schedule STOs also make cross-company accounting simple Aids taxation and compliance audits. Share your own comments and ERP insights today! The STO document is issued at both ends. At Surety Systems , we understand that navigating complex system requirements, handling critical change management procedures, and managing the entire process of implementation or integration can be challenging without the right team or resources. Start connecting it. Report picking of the items from stock: Line-by-line, by clicking the Pick button on each line. We use cookies to enhance your experience on our website. Shipping data for supply plant, One step or 2 step, Availability Group. Try it. Document type, Item category, Availability Check. Step MIRO-Invoice Receipt: The receiving plant enters the invoice from the supply company code or if the invoice receipt is automatically posted in internal billing, the invoice has a payment block. It can be conducted as a one-step or two-step procedure and is not posted at the valuation price of the material in the sending plant but instead defines the price in both the issuing and receiving plants. Shipping point determination configuration Shipping data for supply plant, One step or 2 step, Availability Group Copying Requirement VTFL is the transaction used to define control for copying from delivery to billing document. Join our discussions.

0 thoughts on “Stock transfer order”