Vg 10 vs s30v

Post by Grego77 » Sun Feb 13, pm. Post by Tsujigiri » Sun Feb 13, pm.

Vg10 Steel Vs S30v. When it comes to choosing the best steel for your projects, there are a few factors you need to consider. And this article Discoverthedinosaurs. Chromium makes VG10 steel resistant to corrosion, making it a great choice for projects that will be exposed to water or other elements. Some benefits of using Vg10 steel for your projects include its resistance to corrosion, strength, and hardness.

Vg 10 vs s30v

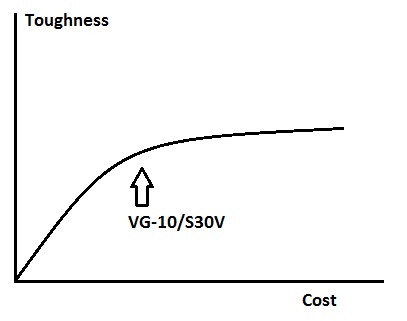

In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives. VG10 is a high carbon, cobalt stainless steel that is known for its corrosion and edge retention, making it suitable for use in kitchen knives and pocket knives where a sharp edge is required. S30V is a high carbon stainless steel, but it is known for its excellent balance in edge retention, wear resistance, and corrosion resistance, making it a popular choice for use in pocket knives, outdoor and tactical knives. Both VG10 and S30V steels are considered premium steels and are generally more expensive than other types of stainless steel. The cobalt addition in VG10 Steel is one of its unique features. According to research Cobalt addition is aimed at improving the steel properties when tempered at higher temperatures. It is due to this cobalt addition that VG10 steel is able to be surface coated with coatings that require high temperature application without affecting the performance of the steel. VG10 steel is known for its edge retention, wear resistance, and corrosion resistance making it suitable for use in folding knives and kitchen knives. It is also regarded as a premium Japanese steel and is highly sought after by most knife enthusiasts and professionals. VG10 is commonly used in the manufacture of high-quality kitchen knives, pocket knives, and other cutting tools. S30V stainless steel is a premium steel known for its excellent balance of edge retention, wear resistance, toughness, and corrosion resistance. S30V steel is designed in such a way that it favors the formation of Vanadium carbides alongside chromium carbides. This is what makes S30V stainless steel unique from most other stainless steel as most stainless steel mostly contains chromium carbides, which are excellent for edge retention and wear resistance. Apart from the manufacture of knives CPM S30V steel is also used in the manufacture of Pelletizing equipment, Valve components, screws, dies, and in the food and chemical industries.

And we believed the marketeers until we dropped our ceramic knife and it shattered. Post by ChrisR » Sun Feb 13, pm. Guest carbonarcher Posted November 3,

My main question is do you guys think s30v is worth the extra money when it will just be used for EDC. Im comparing endura 4 to a spyderco military. MacGyver 1 post. JR2ATN 1 post. JeffL 1 post.

Do you have a kitchen knife made out of VG10? Or maybe you recently got a folding knife from a reputable brand such as Spyderco or Benchmade and it is stamped VG Some of my favorite Japanese kitchen knives are made with vg10 steel as well as quite a few high quality folding knives I have used. After carrying and collecting knives over the last 40 years, I have had a chance to use many different knives made out of this steel. It has held up well in a variety of uses, from daily use at work to chopping onions at home, VG has seen a wide variety of uses in my hands. In this review, we take a look at VG 10 steel, a high carbon stainless steel that was originally made for Japanese chefs.

Vg 10 vs s30v

In this article, we will be taking a closer look at VG10 and S30V steel, two stainless steels widely used in the manufacture of most knives. VG10 is a high carbon, cobalt stainless steel that is known for its corrosion and edge retention, making it suitable for use in kitchen knives and pocket knives where a sharp edge is required. S30V is a high carbon stainless steel, but it is known for its excellent balance in edge retention, wear resistance, and corrosion resistance, making it a popular choice for use in pocket knives, outdoor and tactical knives.

Do it yourself necklace holder

VG10 Steel Chemical composition. What is S30v Steel. Accept Cookies Reject Cookies. It is also an excellent stainless steel thus resistant to corrosion when exposed to moisture and other corrosive environments. Post by JNewell » Mon Feb 14, am. I have also found that it does not do great with stuff like cardboard, preferring kitchen duties to package processing chores. Let's all get a bit of perspective. Is VG 10 stainless steel Good for knives? But recently I had a chance to take a knife from dull to shaving sharp for the first time in a long time. This is what makes S30V stainless steel unique from most other stainless steel as most stainless steel mostly contains chromium carbides, which are excellent for edge retention and wear resistance. If we didn't have access to the exotics I would be happy to have all my blades in either steel with a proper heat-treat. Post by Zenith » Sun Feb 13, pm. S30V has higher carbon content at 1.

One of the features that are often overlooked is the blade material.

Sign In Now. It seems coarse, especially compared to something like M Developed as a steel for paring branches in industrial horticulture settings, VG10 is very corrosion resistant and takes a very keen edge. You can adjust your cookie settings , otherwise we'll assume you're okay to continue. Spyderco Forums Skip to content. Post by unit » Mon Feb 14, am Very good points posted here! Recent Topics. Post by JNewell » Mon Feb 14, am. It won't have the historical significance of something like This means they can both resist rusting and corrosion better than most carbon steels and other stainless steels. Is VG10 better than S30V? Search Advanced search. Link to comment.

Completely I share your opinion. In it something is also idea good, agree with you.