Waste heat recovery helps in mcq

How good are you at mechanical engineering? You can take these emerging trends in mechanical engineering MCQ quiz to check your knowledge of the latest technologies.

Which of the following depends on physical properties of fluids as well as geometry of the heat exchanger? The efficiency of a stand-alone gas turbine without any heat recovery system will be in the range of. The waste heat recovery equipment in a combustion system will be more economical when the exit flue gases are at a temperature of. In an industry, exhaust gas from the furnace is used for power generation by installing waste heat recovery steam boiler and a steam turbine. This type of co- generation is termed as. In a cogeneration system, with extraction condensing turbine, the highest heat rate is recorded when;. Calculate the reduction in pressure drop in meters when pipe diameter is increased from mm to mm for a length of meters.

Waste heat recovery helps in mcq

B a Fixed carbon b Volatile matter c Hydrogen d All of the above 23 Which one of the following boilers utilizes the combination of suspension and A grate firing? Oxidation of CO to CO2 will yield a kCal b kCal c kCal d kCal 48 The maximum loss that takes place in a fully condensing steam turbine power D plant is a Flue gas loss b Steam distribution loss c Radiation and insulation loss d Condenser losses 49 The difference between mean solid and mean gas velocity in FBC boiler is called B a Fluidization factor b Slip velocity c Settling velocity d Terminal velocity 50 Which one of the following is a high temperature heat recovery device? Then the type of co- generation is called as: a gas turbine b diesel generator c topping cycle d bottom cycle 73 1. Open navigation menu. Close suggestions Search Search. User Settings. Skip carousel. Carousel Previous. Carousel Next. What is Scribd?

The organic Rankine cycle is a thermodynamic cycle that uses an organic working fluid to convert waste heat into electricity.

The most efficient solution of heat supply at low and medium temperature is: a. Using a fuel that is directly combusted in the energy consuming equipment. Using electricity. The most consumers of heat at low or medium temperature are supplied with heat using as energy carrier: a. Water in different forms. Compressed air. Flue gasses.

With most of the world committed to limiting global warming to 1. As we approach the end of , we have only six years left to implement many decarbonization levers. But industrial companies are often uncertain about the right technical path to immediately reduce emissions. Technologies that are net present value NPV positive and quick to implement, such as various types of energy efficiency measures, can help companies achieve their decarbonization goals. Recovering waste heat is a potential avenue to effectively reducing emissions. Every year, the world consumes over exajoules EJ —or , terawatt-hours TWh —of final energy, mainly by burning fossil fuels and generating heat.

Waste heat recovery helps in mcq

Of this, around one third is wasted. This wasted heat can be lost to the atmosphere at all stages of the process; through inefficient generation, transmission or final use of that energy. Waste heat recovery aims to minimize the amount of heat wasted in this way by reusing it in either the same or a different process. Waste heat can be recovered either directly without using a heat exchanger—e. Direct heat recovery is often the cheaper option but its use is restricted by location and contamination considerations. In indirect heat recovery, the two fluid streams are separated by a heat transfer surface, which can be categorized as either a passive or active heat exchanger. Passive heat exchangers require no external energy input e. When considering waste heat recovery, the key question is always that of financial justification: "How much money will be saved? As a general rule of thumb, a waste heat recovery project is unlikely to be installed if its payback period is longer than two or three years. When describing waste heat recovery it is important to specify the nature of the waste heat in terms of temperature and material phase.

Kamil koç dudullu

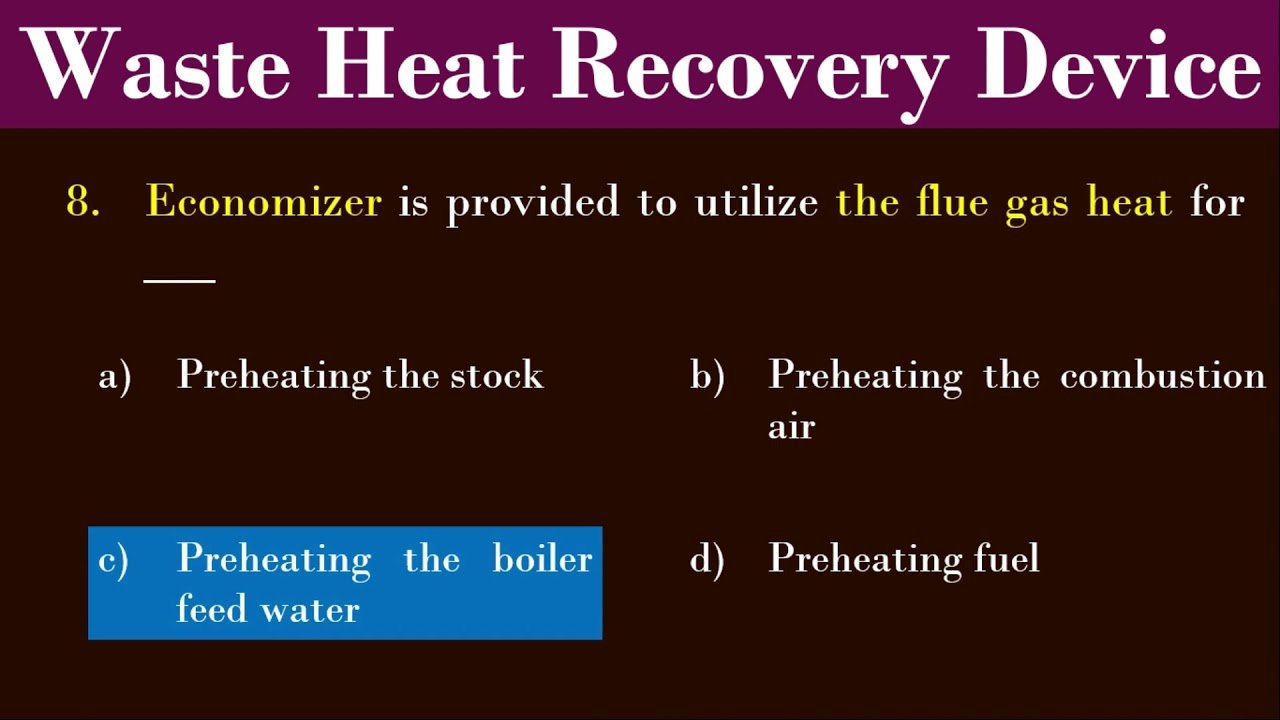

Combustion and Flame 6. It is specifically designed to prevent the loss of steam while efficiently removing condensate, ensuring the smooth operation of steam systems. Learn about Our Editorial Process. Mechanical Design, variant 1, midterm exam Mechanical Design, variant 1, midterm exam. Shubham Agarwal. Explanation A micro-hybrid system is primarily used for Start and Stop Technology. Economizer increases the efficiency of the power plant. This technology is commonly used in various applications such as industrial machinery, automotive systems, and aerospace. Feedback During the Quiz End of Quiz. During this process, the fuel undergoes a reaction with oxygen from the air, resulting in the production of electricity and water as a byproduct. Hydrogen generation by using exhaust gas waste heat involves using the waste heat from exhaust gases to produce hydrogen.

.

Related Quizzes. The electric motor assists the engine during acceleration and at low speeds, reducing fuel consumption and emissions. Fouling coefficient. This means that for every kilogram of the battery's weight, it can provide watt-hours of energy. Last updated on Jul 27, Radiation recuperators are used when the furnace flue gas temperature is more than. Oxidation of CO to CO2 will yield. Adjusting airflow rates to suit changing occupancy conditions and use of building space within heating, ventilation and air-conditioning system is: a. The shape of the tower allows for better air circulation and flow, increasing the efficiency of the cooling process. Explanation All of the options mentioned - hydrogen generation by using exhaust gas waste heat, thermoelectric generator, and organic Rankine cycle - are considered advanced WHR waste heat recovery technologies.

Talently...