Welding 7018 vertical up

View Case Studies, Video Stories, Technical Articles for guidance on welding various metals and what filler metals to use in your industry.

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive. Remember Me? Advanced Search. Results 1 to 24 of Thread: What is the secret to vert up?

Welding 7018 vertical up

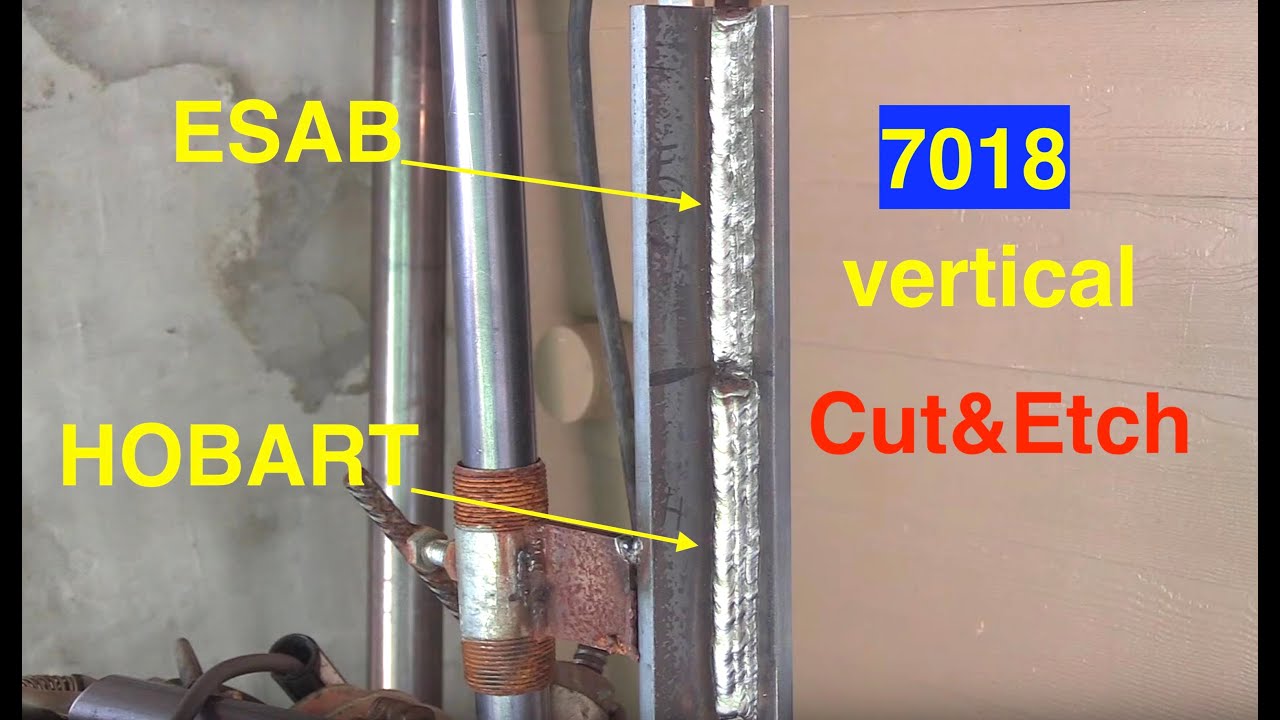

Figure 1 SMAW, or stick welding, requires a certain mastery of skills, and vertical and overhead stick welding is that much more difficult-one of the reasons the specialty is in such great demand. Vertical and overhead stick welding have never been in such high demand. Heavy construction continues see Figure 1 in the southeast U. Ironworkers, pipe fitters, boilermakers, and shipbuilders are working to meet a new global demand for development and energy. At the core of this work lies an advanced welding position that requires skill beyond the preferred horizontal position—vertical-up shielded metal arc welding, or stick welding. Flat and horizontal welding positions lend themselves to faster work, but sometimes vertical or overhead welding with a stick electrode cannot be avoided. If that's the case, here are five tips to help you do it well. Fighting gravity is the main challenge in vertical-up welding—or any position that is 45 degrees or steeper. Stick electrodes with an AWS classification of are considered the first choice because of their low iron powder content see Figure 2. The molten metal produces a puddle that can freeze quickly and is less inclined to drip off the work during its liquid state. AWS also can be used for similar reasons, but allows a faster weaving pattern.

One error to avoid while weaving is undercutting.

Powered by mwForum 2. Not logged in American Welding Society Forum. By elliott Date I have gotten alot great answers to my other question on vertical up. But know that have been practicing I cant seem to get the bead to flatten out like it does running in the flat postion, I dont know for sure it is dropping but it does not flatten it got hump in the middle of the weld. And on other question on gettig certified. I work for an awning compay and we have been getting into bigger stuctures such as 10x10 coloms and they want everybody to be certified but at the shop the foreman doesnt buy or rod we only use or can you get certified using that rod.

When it comes to welding with the electrode in the vertical position, several factors play a crucial role in achieving a successful weld. Let's discuss the importance of amperage, polarity, arc length, and rod angle in this context:. Overall, paying attention to amperage, polarity, arc length, and rod angle is helpful for vertical welding with the electrode. Stronghand Tools. Tig Fingers. Tig Kits.

Welding 7018 vertical up

When you are welding uphill with …or any other rod for that matter, you typically will use less amperage than you would for flat or horizontal welds. So how hot is hot enough? So here is what I did… First joint was done at amps. Then I cooled the metal all the way before increasing amperage to amps…then I cooled it off again and increased amps to At amps, I could tell, things were going to get out of control if I went any hotter, so I cooled the piece and welded the last joint at amps. In Stick Welding, there is something called the Clams Acronym that helps to remember the essential things that go into a good weld. Not forcing it into the puddle, but very tight. Angle I tried to maintain a 90 degree rod angle knowing that I would probably get into a slight push angle…just seems to happen with the helmet drops Manipulation of the rod slight manipulation helps me see where I am going but allowing the light to change. A slight manipulation of the electrode can also help to flatten out the face of the weld Speed of travel A general rule of thumb in stick welding is to travel slow enough not to leave undercut…. Also, when you are using a slight manipulation technique, its important to pause at the edges of the weld to let them fill with weld.

Suitsupply

Always consult with the specifications and codes for the requirements on each job. When doing a vertical weld with , you can get away with slightly higher amps by using an extreme push angle. Pictures would help some of these guys diagnose your problem Can you read the puddle yet? Turn your heat right up to amps. Vertical and overhead stick welding have never been in such high demand. These cookies will be stored in your browser only with your consent. Again, each puddle should be roughly 1. Sometimes simply reducing the puddle size improves operator control. Consistency needs some work as well, but overall I've seen a lot worse from guys. Heavy construction continues see Figure 1 in the southeast U. Just try running a bead on plate and see how much push angle you can get and still burn the rod.

And if a WPS specifies stringer beads as opposed to a weave, then you need to use stringer beads.

The pipe outer 4 inch weld was done out of position. Punching and Other Holemaking. Subscribe to The Fabricator. To help along the way, consider these details. Techniques Proper technique is always important during welding and using an E stick electrode is no exception. Great write up I have used this rod as a go to rod for 30 years. But opting out of some of these cookies may affect your browsing experience. In addition to the standard AWS classification, E stick electrodes can also have supplementary designators such as H4 or H8. I find the puddle wets in much better if you're running up some sort of fillet, lap joint etc, rather than just stringers on a plate so you may want to just tack together a bunch of joints and run multiple passes on those to start out. About certifying; will you be certifying on groove welds or fillet welds? A electrode will help overcome poor surface conditions, but it takes more time and skill than weaving with Manufacturing Software. You have a fresh can of Excalibur

Yes, really. It was and with me. Let's discuss this question.