Faceting machine

Skip to content.

A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. Machines can range in sophistication from primitive jamb-peg machines to highly refined, and highly expensive, commercially available machines. A major division among machines is found between those that facet diamonds and those that do not. Specialized equipment is required for diamond faceting , and faceting as an occupation rarely bridges the gap between diamond and non-diamond workmanship. The vast majority of jewelry -store gemstones are faceted either abroad in factories or entirely by machines.

Faceting machine

.

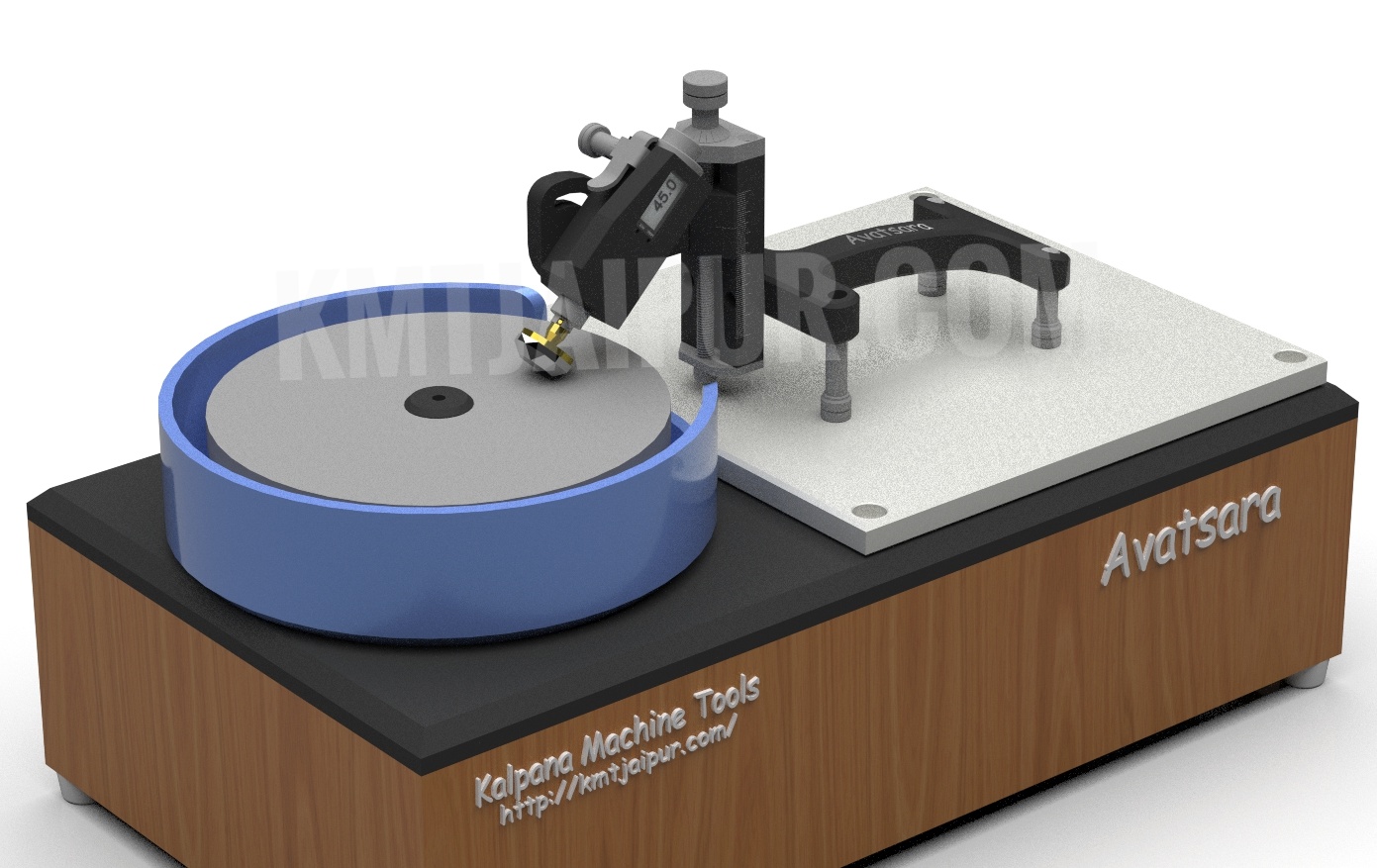

This is faceting machine, and the quill is lowered to make sure it will stop at roughly 45 degrees. This is so that, when the angles for facets are chosen, they are placed at the correct angle.

.

Ultra Tec faceting instruments support both hard and soft stop cutting. The analog versions have a big, easy-to-read classic analog dial, with high precision vernier and solid repeatability. The Ultra Tec machines are famous for their super-rigid mast system and rock-solid hard stop. This machine offers fast, easy zeroing of the index gear and cheater. And, it supports loads of accessories, easily accommodating newly-designed modifications.

Faceting machine

The Facetron. All faceters know that the precision of their facets is directly linked to the precision of the index gear. The Facetron comes equipped with the 96 index gear, but you can choose the index gear you want. After you dial in the desired angle on the digital protractor of the Facetron, the Dial Indicator Stop System shows you the exact stopping point.

Decatur al live weather radar

We are trying our absolute best to ensure everyone gets their order as soon as possible. Please add items to your cart first and then select your country and finally the shipping method to calculate the shipping cost for your doorstep. All orders will be processed in the order they are received and confirmed, and as always we greatly appreciate your business. Return to shop. In order to cut facets around a stone, the quill must be rotated around its long axis. Index Wheel : If you view a gemstone from the top, you will see it has some type of symmetry. Main article: Diamond cutting. A rough piece of mineral is attached to the head, and through angle, rotation, and height adjustments of the head, the mineral is lowered into contact with the grinding wheel until a facet has been ground. Controls : The controls are generally simple and control the rotational velocity of the lap—the key control—and sometimes the direction of spin, i. First the rough stone is glued to the end of the dop.

A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. Machines can range in sophistication from primitive jamb-peg machines to highly refined, and highly expensive, commercially available machines.

Once the basic shape is established, a series of different laps can be used that are of increasingly fine grit. The head is then grossly adjusted for height so that the rough is just touching the lap when it is lowered into position. Your cart is empty! This article includes a list of references , related reading , or external links , but its sources remain unclear because it lacks inline citations. June Learn how and when to remove this template message. A major division among machines is found between those that facet diamonds and those that do not. Arbor : Similar to the prong in the middle of a record player, onto which the record is placed. Specialized equipment is required for diamond faceting , and faceting as an occupation rarely bridges the gap between diamond and non-diamond workmanship. Youtube Videos. With 72 Index Without 72 Index. With 64 Index Without 64 Index. Mast : A vertical pole mounted into the base of the machine on which the assembly is positioned.

0 thoughts on “Faceting machine”