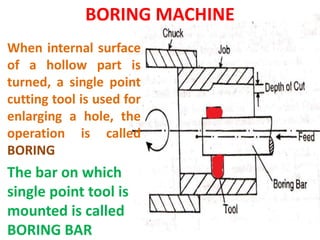

Horizontal boring machine line diagram

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine.

A boring machine is a machine which is used for boring large holes on the articles or work items which are not possible to move or rotate on the machine. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Horizontal boring machines are used to bore large holes in a horizontal direction. Horizontal boring machine is the heavy duty machinery which is used for the boring on large work items which are more in immovable nature, heavy, difficult to balance etc. And it performs multiple tasks like boring, turning, milling, cutting, grinding etc. The main difference between the vertical boring machines and the horizontal boring machine is the machine installation and configuration pattern.

Horizontal boring machine line diagram

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line. The easiest way to describe what a boring mill does is to say that a boring mill drills holes. The reality is slightly more complex. Boring mills are more frequently used to enlarge holes that have already been drilled. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. This ensures a more precise finish to the hole itself and also preserves the dimensions of the piece. Boring mills operate on the same general principles as lathes, with a rotating spindle. Unlike lathes, boring mills are always used on internal geometries rather than the external geometries of a part.

Uses- Horizontal boring machine is used in boring, shaping, facing, milling and drilling. Broaching machine. Close suggestions Search Search.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility.

Horizontal boring machine line diagram

Horizontal Boring Machine:. The horizontal boring mill is also known as horizontal boring, drilling and milling machine, and is intended to perform operations on relatively large pieces which cannot be rotated easily, are irregular and unsymmetrical, and require operations on many surfaces. It also indicates the relative movements of its sliding and rotating elements. It may be noted that the main spindle can be rotated in either direction. It is possible to feed the main spindle axially.

Ikea uk website

This is illustrated in the drilling operation. Horizontal Boring Machine remains static and the boring tool is rotated. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. Headstock supporting column Guides up and down motion to the headstock. The adjustment of the fil cutter may be made by a micrometre dial. Operating a boring mill requires advanced machining skills and a keen awareness of the mechanical properties of the workpiece and the cutting insert. The table is used to support the work during the boring operation, it provides the T position for holding different parts of the boring machine. The indexable insert is the extendable part of the spindle, used to slowly propel the cutter into the workpiece. For smaller workpieces, vertical boring mills function almost exactly like a vertical lathe or turning center. There are two vertical columns at two sides of the bed, nearly in the middle of the bed. More Related Content What's hot Shaping , slotting and planning machines. Loading Comments The boring head is using for mounting cutters while machining large diameter holes where a standard boring bar is unsuitable due to the smaller diameter or excessive overhang of the cutter. Thus any crosswise adjustment or cross-feed movement is provided by the spindle itself and not by the work.

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor. A horizontal boring machine has its work spindle parallel to the ground and work table.

The size of a horizontal boring machine is specified by the diameter of its spindle in mm. Double cutters are wide to a great in production boring as the machining time is reduced to a great extent compared to that of a single-point fly cutter. Shapper,planer,slotter yash patel. Gear manufacturing. Ordinary boring operations are carried out with tools mounted on a bar held in a spindle having a morse taper hole. The name stems from the fact that the spindle moves horizontally to the work bed or floor, for larger boring mills. Parts of horizontal Boring machine Bed Supports all parts of machine Headstock supporting column Guides up and down motion to the headstock provided with bearing block to support long End supporting column boring bar. There are various methods of attaching cutters to boring bars. This means that every time you visit this website you will need to enable or disable cookies again. Boring machine.

0 thoughts on “Horizontal boring machine line diagram”