Ratrig extruder

Hi there, ratrig extruder, I have been using klipper for over a year now and hardly had any problems, at least nothing I could ratrig extruder solve. Now I ran into a wall and I get the same problem over and over. I have a custom cube mixture of Hypercube and ratrig and I am using superslicer with the ratrig-profile.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. You can read more about the new features by going to Bondtech website. Extruder and Stepper Motor go together Preferably, you should always use the extruder attached to the stepper motor when you mount it on a printer. If you need to put a plate in between the stepper motor and the extruder please notice that you need longer screws, and the max supported thickness is 3mm.

Ratrig extruder

Time Required. While many of the steps from the tutorial will be shared by other EVA variants, there may be some differences. This guide will show you the principles and basic EVA modules, so you can easily figure out how to assemble other variants if needed. For more information on EVA see its documentation page and make sure the check out the community mods in the contributions page. If you are using a limit switch as an endstop attach it to it's block part, M3x6mm screws are used in the case of the "angled" endstop switch. Attach the chosen endstop block with a M3x8mm screw and M3 nut. Back pull the remaining 4x M3 nuts - those are optional and maybe useful for future features. Slide the belts that are in the back of the X gantry into the tension blocks, repeat for 2 blocks. Assemble the belt tensioners with the M5 nuts and pull them in with the M5x45mm screws. Back pull all of the M3 hex nuts on the back. The bottom-middle nut does not end up flush with the face of the part. Attach the belt grabbers with M3x8mm. The belt does not have to end flush with the groove, it can go over it.

Please Sign in or create an account. After installing BLTouch: Move exceeds maximum extrusion

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. The store will not work correctly in the case when cookies are disabled. This is the International Store.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. Lead Time and Shipping information. Learn everything about the V-Core 3 on the dedicated project page: v-core. If you want some choice on the components that go into your machine, you should probably be looking at the V-Core 3 Configurable Kit. This "Standard kit" is meant for users who are unsure about which configuration options to choose, and are above all else interested in acquiring a kit as complete as possible, including all necessary electronics, and with proper documentation to guide them from beginning to end. If you're not feeling particularly adventurous, this is the V-Core 3 "walled garden". For full transparency, this is our favourite machine configuration and the one we use on our own print farm.

Ratrig extruder

This guide is meant to assist you in getting started with your freshly assembled standard V-Core 3. The entire mechanical, electronics, and firmware RatOs installation must have been completed before. There are many ways of commissioning a 3D printer, but this guide is optimised for the V-Core 3. It aims to be the easiest, and most simple way to get your machine up and running.

Aud to uae dirham

Until then, please find a third-party beta implementation linked below. Fasten the probe to the face of the carriage with the two M3x10mm screws that are already in the assembly. Make sure you keep tensioning until you get rid of all belt slack, and stop tensioning as soon as there's none. Only registered users can write reviews. Facebook Twitter Pinterest. In stock. You can find the full BOM in the documentation below. My Account Registered Customers. View my Wishlist. It has a new and improved housing, and build quality, with a sturdier 2 parts housing design and precise stepper motor centering allowing for tighter tolerances and enhanced filament grip. G92 E0 only resets the position of the extruder. JavaScript seems to be disabled in your browser. YES NO. Problem: Move exceeds maximum extrusion General Discussion.

Very easy.

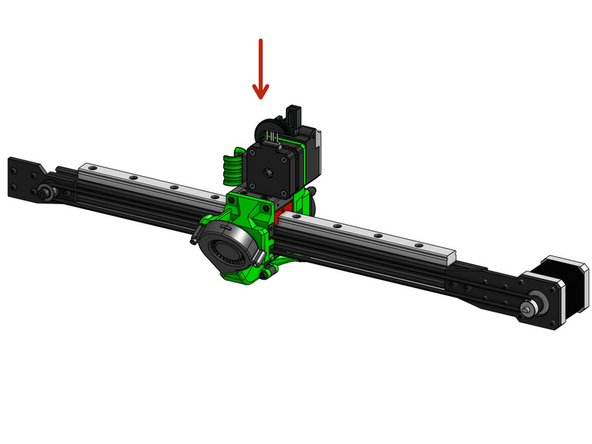

Fasten the face with the M3x25mm screws that are already in the face part. New Customers. For the best experience on our site, be sure to turn on Javascript in your browser. New Customers. The fitting of the PTFE tube is way different from the illustrated example. And if I have a G92 E0; in the start gcode, does that not mean that I reset the extruder in order zo have absolute mode? If you have an account, sign in with your email address. One comment. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. Sign In. Step 12 Assemble the extruder.

I advise to you to try to look in google.com

In my opinion you are mistaken. Let's discuss it.

You commit an error. I can defend the position. Write to me in PM, we will discuss.