Whitworth thread chart

Documentation and policies. Business model. What sets us apart. Shareholder information Investor profile Frequently asked questions Advisers Guidance to shareholders Glossary of terms Shareholder meetings Total shareholder return.

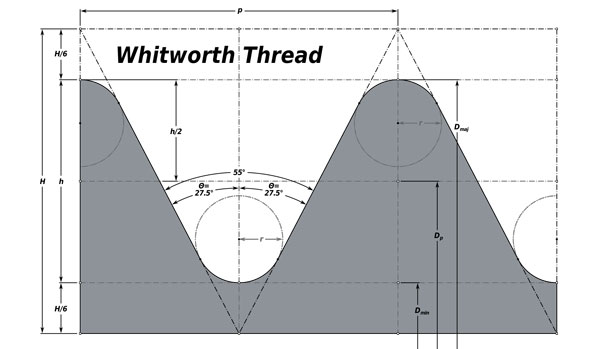

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram. The principal features of the British Standard Whitworth BSW thread form are that the angle between the thread flanks is 55 degrees and the thread has radii at both the roots and the crests of the thread. The relevant standard for this thread form is the British Standard BS 84 - The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used.

Whitworth thread chart

The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering. This is more like the modern "mechanical" screw and was used for fine machinery and steel bolts. TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener. TPI is used only with American fasteners. Metric Fasteners use a thread Pitch. In general, smaller fasteners have finer threads, so the thread count is higher. The thread pitch is the distance between threads expressed in millimeters.

TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener, whitworth thread chart. Companies that initially converted to metric threads have converted back, after complaints that the finer metric threads increased the time and whitworth thread chart of setup, which often takes place at the top of a ladder or scaffold.

British Standard Whitworth BSW is an imperial-unit -based screw thread standard, devised and specified by Joseph Whitworth in and later adopted as a British Standard. The Whitworth thread was the world's first national screw thread standard, [1] devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. The thread pitch increases with diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic.

Supplier of industrial fittings and hoses. Whitworth thread is the British national thread type developed in by Joseph Whitworth. Prior to that, there were no generally accepted standards. Each company had its own standards, which led to a lot of confusion. Whitworth threads were the answer to this difficulty, and the fact that we still use them today is testament to the effectiveness of such standardisation. The Whitworth thread standard is described by specific abbreviations that you will find on today's construction parts.

Whitworth thread chart

Most of us think of car parts in terms of carburetors, engines, transmissions, brakes, and so on. Much maligned and misunderstood, the Whitworth hardware used on older British cars has an interesting history. Threaded fasteners go back a long way. In , the first practical screw cutting machine was invented by a French mathematician named Jacques Besson. After that, things took off…after a fashion. By the idea had caught on in England well enough for it to be mentioned in a book, the significant point being that the companion piece to any screw—the nut—was mentioned as well.

Gasket for washing machine hose

Environment and climate change. Enclosure Hardware. It was a fine pitch thread having 32, 40 or 60 tpi. Tooling and Driver Bits. ISBN In both cases the spanner jaw width of 0. Toggle navigation. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:. In the US, BSW was replaced when steel bolts replaced iron, but was still being used for some aluminium parts as late as the s and s when metric -based standards International Inch replaced the U. Wikimedia Commons. Heavy vehicle. Suddenly, by a flash of the mechanical genius which was inherent in him, the late Mr John Penn solved the difficulty, and solved it quite easily.

Documentation and policies. Business model.

Trade bodies and associations. In other projects. Fasteners for Sheet Metal. What sets us apart. Documentation and policies. British Standard Brass for which there is no British Standard is based upon the Whitworth thread form with all diameters having 26 threads per inch tpi. British Morris and MG engines from to were built using metric threads with bolt heads and nuts dimensioned for Whitworth spanners and sockets. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic. The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in Model Engineers ME Threads Established in , the Model Engineers thread is based upon the Whitworth thread form and was used in instrumentation as well as by model makers. The thread may have come about as an attempt at standardisation by gas burner fitting manufacturers. In general, smaller fasteners have finer threads, so the thread count is higher.

Bravo, brilliant idea

I consider, that you are mistaken. I can prove it. Write to me in PM, we will discuss.