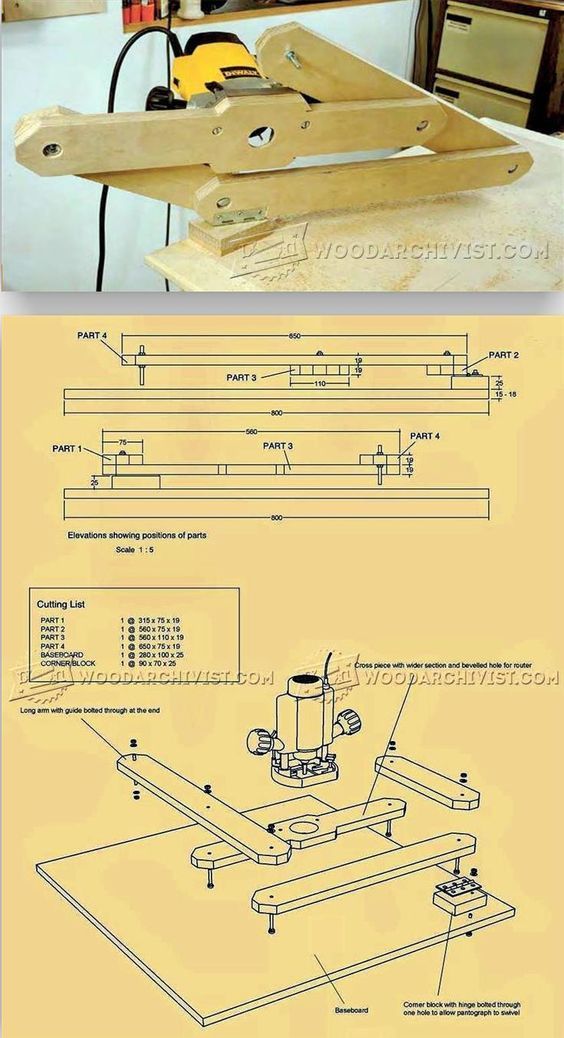

Diy router pantograph

Log in. Sign up. Journals Projects Workshops Reviews. JavaScript is disabled.

Anything you can print out, you can rout. The only Pantograph that comes mostly assembled right out of the box. This is a complete routing system; including 3 router bits, 3 stylus tips, 2 stencil fonts, and line drawings. All necessary hardware is included, all you need is your router and wood. Follow the design with your stylus and let the router do the work! TurnLock Base plate compatibility chart and template. Thank you.

Diy router pantograph

I drew up the initial CAD model for the pantograph in Google SketchUp, but to turn a CAD model into a nice plan with dimensioned drawings takes a lot of time, and I didn't want to do that until I was sure that my pantograph would work. So I used my BigPrint program to make multi-page full scale printouts from the CAD model without labeling any of the dimensions. With all sizes on even or half centimeters, I could measure off the drawings to get the sizes. I arranged all the curved parts together on one drawing, and cut those out with the bandsaw. I'm using 18 mm baltic birch plywood for the router mount, though other high quality plywood could also be used. With a fine blade in a properly set up bandsaw, it's possible to follow lines very closely. It's better to cut this with a bandsaw than to use a circle cutter because with a circle cutter, if you get the center position or radius just slightly off, the whole circle will be off. Whereas if you go outside the line just briefly with the bandsaw, it won't throw the whole circle off. The one-to-one scale drawings also came in handy to check the parts. It was easy to make sure that I had produced all the parts and to the correct size by arranging them on the drawing. So I included more views in the plans I drew. I'm making the straight parts out of maple, though plywood could also be used for these. First I glued the router mount frame together without the top layer. That way I didn't need to worry about getting everything aligned all at once.

PantographPRO is more versatile than a SignPro, as there are no limits to the fonts one wants to use.

Pair up the boards of the same size. One will be the top and one will be the bottom of each piece of the pantograph. On the bottom board, depending on the size of the rotary tool, drill a 1" hole in the middle, 1" from the side. The hole will need to go all the way through the wood. The tip of the rotary tool will go into this hole. Depending on the size of the rotary tool, on the top board drill a 2" hole in the middle, 1" in from the long side. It will cut through the side of the board and needs to go all the way through.

Although I include printable templates in the plans, I figured this time I'd just draw the shape from the drawings on my tablet. This was partially inspired by windows 10 not getting along that well with my printer, and partly to show that you can build the pantorouter even if you don't have a printer. The most complicated shapes are the router mount, but it really didn't take that long to draw it from dimensions on a piece of plywood. I used an empty yogurt cup to draw the arcs that join the main arc and the straight part of the router mount. I cut it out on the bandsaw.

Diy router pantograph

A Pantograph is a drawing aid that simplifies the enlarged copying of pictures or figures. It makes a great educational toy for families with children, or for people who are into craft activities like patchwork, woodworking, modelling, etc. Below, my Dad describes the design he built.

Buyee zenmarket

Very kool. Joined Feb 1, You can see more photos of this build here. The welcome sign shown is 6" by 24". Later you may need to size these with a knife or the rotary tool to make the rotary tool fit. That sure has a large range, too… A few chamfers need to be cut to give the pantograph its full range of motion. Instructions are not very good. The screws supplied may not fit your router. Joined Oct 26, OMG I hope not we need to still get our exercise too!! Thanks for posting the pantorouter link. The pantograph can change the copy size to larger or smaller, depending on how it is designed. Jim, It does have a large range. JavaScript is disabled.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The idea is simple: you move a stylus over a stencil of a letter or a drawing and the PantographPRO transfers that movement to the router, which makes exact copy in scale half the size of the stencil in the wood or some other material. Took a but of time to make the jig for it. Post by John Hill » Tue Jan 24, pm. The end where the rod is sticking through needs to hang over the board so it can move around. Depending on the bit and material, it will be different. I am actually looking at building Mathius's scale duplicator. Nice build job. However, I considered stability and weight and decided that 2X the original design was plenty large enough. That is wicked cool…I hope you post a few items you've panographed later…. With a fine blade in a properly set up bandsaw, it's possible to follow lines very closely. There could be adjustable templates of angles, curves a shipbuilder's spline, for example. Tape your pattern on to the board where you will be working.

In my opinion it already was discussed.

It is remarkable, it is a valuable piece

I like this idea, I completely with you agree.